Have you ever found yourself in need of a specialized abrasive that meets the unique demands of your industrial projects? If so, 3M’s Trizact Cloth Belt 217EA might just be the solution for you. With its innovative design and advanced technology, this cloth belt is well-suited for a variety of applications, particularly in the realm of intermediate finishing and fine polishing. Whether you’re working in a robotics environment or focusing on detail-oriented projects, understanding the specific features and benefits of this belt can make a world of difference. Below, let’s look into the product details, benefits, usage, and what makes it stand out in the market.

Product Overview

The 3M Trizact Cloth Belt 217EA, with its A65 JE-Weight, 2 in x 148 in dimensions, is an innovative abrasive tool designed to deliver consistency and longevity. This product has been engineered specifically for industrial use, making it a standout choice for professionals in need of reliable and high-quality abrasive solutions.

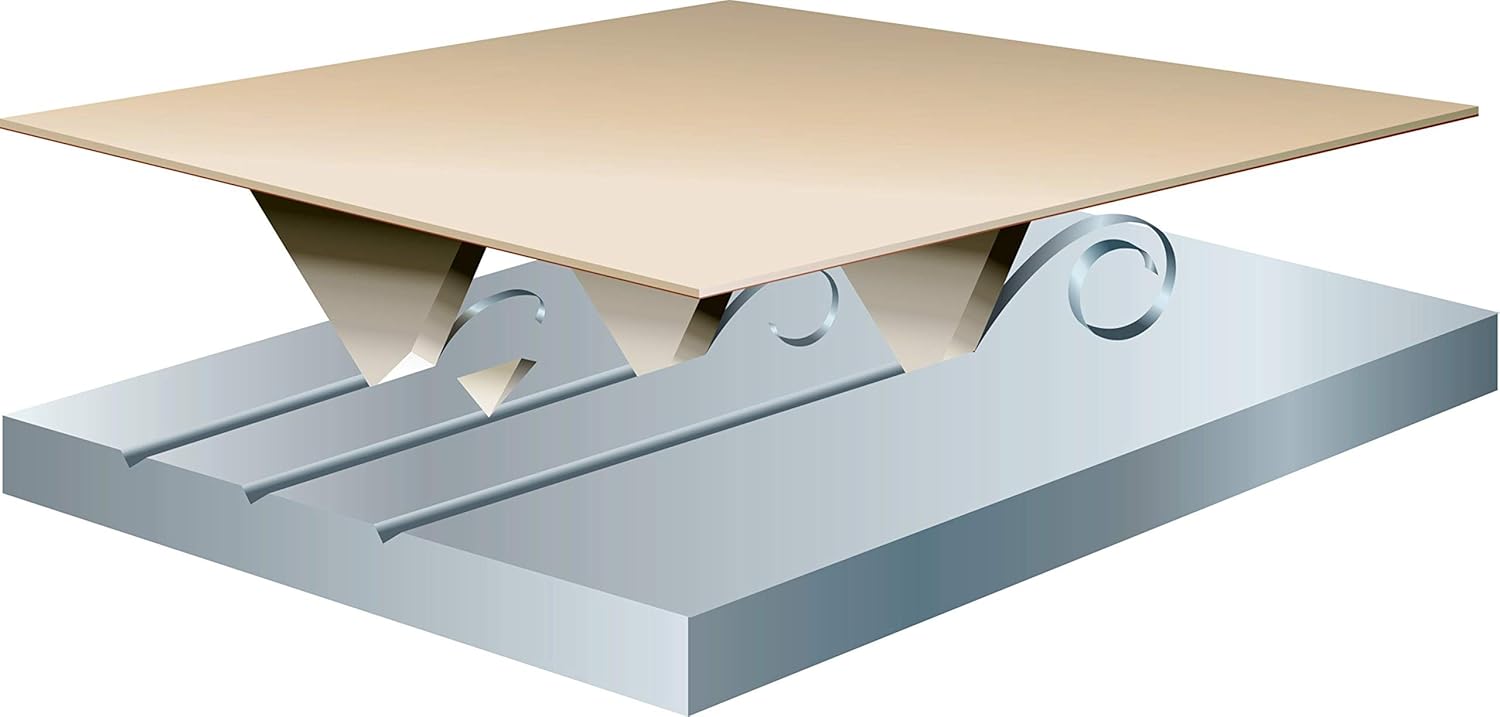

The Trizact technology, featuring microreplicated pyramids, is designed to wear away gradually. This exposes a fresh layer of mineral, ensuring a consistent cut throughout the belt’s lifespan. This quality translates to less frequent replacements and a uniform finish, even on complex surfaces.

Key Features

Microreplicated Pyramids

One of the defining features of this belt is the microreplicated pyramid technology. By design, these structures wear away to reveal fresh mineral layers. This means you can count on a consistent cutting performance from start to finish, maximizing both efficiency and outcomes in your projects.

Flexible JE-Weight Cotton Cloth Backing

The backing of the cloth belt is made from JE-weight cotton, which is flexible enough to flow over contoured surfaces. This adaptability makes it ideal for parts that are not perfectly flat, providing consistent finishing across various shapes and surfaces. The flexibility also contributes to an even finish without sacrificing strength.

Benefits of Using 3M Trizact Cloth Belt 217EA

The benefits of using this cloth belt are multi-faceted, especially if you’re aiming for a balance between precision and durability.

Consistent Finishing

Thanks to its microreplicated design, the belt efficiently exposes fresh abrasives, maintaining a steady finish. This feature is incredibly valuable in industrial settings where precision is key, such as when preparing materials for plating or buffing.

Durability and Longevity

Given its engineered composition, the belt’s longevity is noteworthy. The durable nature of the cloth belt means fewer replacements and potentially lower costs over time, boosting overall efficiency.

Versatility in Applications

The belt is versatile enough for varied applications. It excels in intermediate finishing and fine polishing tasks, making it a versatile choice for industries that require detailed surface preparation.

Ideal Use Cases

This belt is particularly well-suited for robotic applications and light pressure uses. For environments that utilize robotic tooling, this belt shines by providing a consistent abrasive surface, which is necessary for automation precision.

Intermediate Finishing

For tasks that require intermediate finishing, the Trizact Cloth Belt 217EA provides a consistent and controlled cut that helps in achieving the necessary smoothness while conserving time and resources.

Fine Polishing

Before plating or buffing, a fine polish is often crucial. The cloth belt offers the capacity to achieve the finesse required in these preparatory stages, ensuring surfaces are optimally prepped.

Product Details at a Glance

Let’s break down the main aspects of the 3M Trizact Cloth Belt 217EA in the table below, summarizing the features, advantages, and potential applications for easier reference:

| Feature/Specification | Details |

|---|---|

| Abrasive Technology | Microreplicated pyramids for consistent cut |

| Belt Composition | JE-weight cotton cloth |

| Belt Dimensions | 2 in x 148 in |

| Suitable Applications | Intermediate finishing, fine polishing, robotic applications |

| Ideal Use Cases | Light pressure applications, contour finishing |

| Durability | High, allows abrasive to break down for maintained cut |

| Regulatory Note | For industrial/occupational use only |

| Market Goal | Not for consumer sale |

Performance in Action

Robotic Applications

The 3M Trizact Cloth Belt 217EA is engineered for robotic applications where consistent performance is non-negotiable. The precision in design aids robots in maintaining uniformity, which is critical in automated finishing systems.

Light Pressure Applications

In scenarios requiring light pressure, this cloth belt proves to be efficient and effective. The abrasive design achieves the desired finish without necessitating excessive force, making it an excellent choice for fine-tuning and polishing tasks.

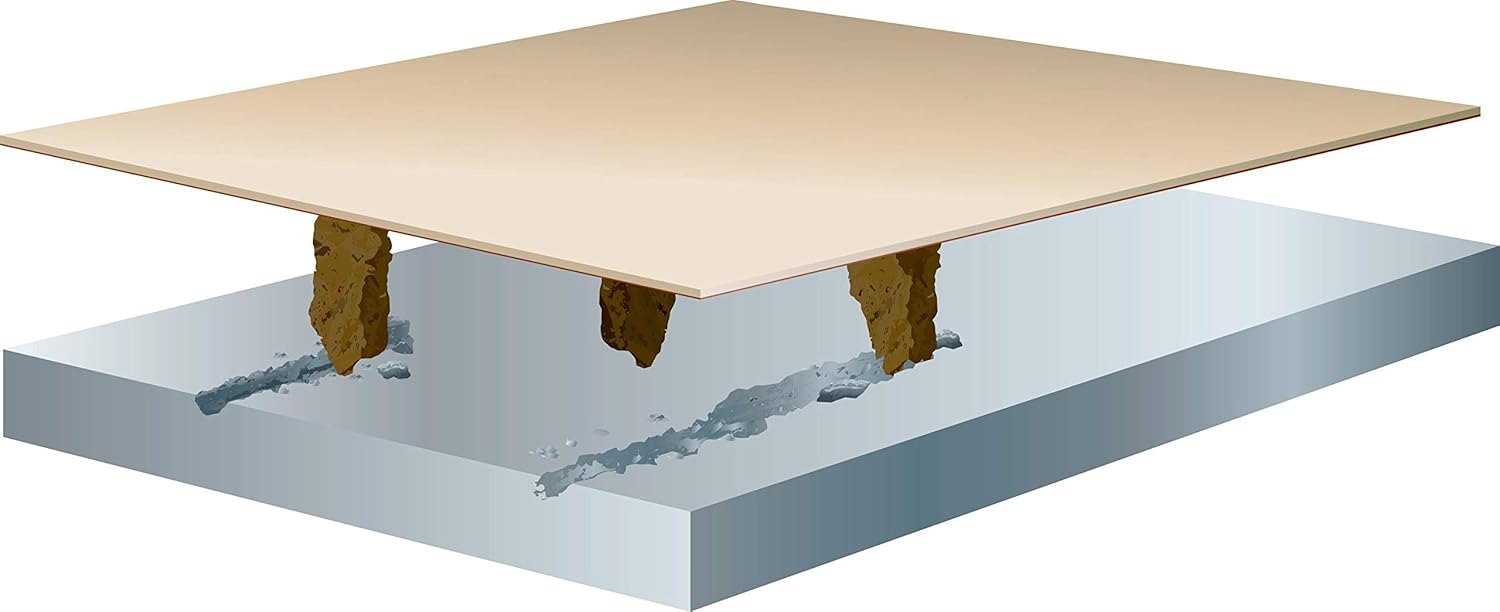

Comparisons with Conventional Abrasives

When compared to traditional coated abrasives, the 3M Trizact Cloth Belt 217EA stands out due to its design targeting finer finishes. Its ability to maintain consistent cutting and longevity provides an edge in quality and cost-effectiveness over time.

Finer Finishes

Where typical abrasives might falter, requiring frequent changes or less-than-ideal results, the Trizact provides a much finer finish. This is because the abrasive surface refreshes itself constantly, unlike conventional options that may dull with use.

Cost-Effectiveness

The durability this belt provides means fewer replacements, saving on maintenance time and supply costs. This factor alone offers an advantage for industrial operations seeking to optimize their budget without compromising on quality.

User Testimonials and Feedback

Many industrial users have lauded the 3M Trizact Cloth Belt 217EA for its reliability in maintaining consistent finishes across varied applications. Feedback often highlights its efficiency in robotic settings and its ability to handle light pressure polishing with finesse.

Positive Reviews

Users appreciate the belt’s ability to work over contoured surfaces without losing its cutting edge. Many find the balance of flexibility and durability to be a critical advantage over more rigid, traditional options.

Constructive Feedback

While generally positive, some feedback could suggest that users need to ensure they are using the cloth belt under the conditions it’s suited for—mainly those involving lighter pressure and intricate finishing to truly benefit from its specific design attributes.

Conclusion: Is It Right for You?

The 3M Trizact Cloth Belt 217EA is designed for users within industrial and occupational settings who demand precision, durability, and fine finishing capabilities from their abrasives. If your projects align with intermediate finishing and fine polishing needs, especially within robotic applications, this might just be the product you’ve been seeking.

While it is not designed for consumer use, its performance capabilities and technology-driven design make it a worthwhile investment for professional environments. By offering a blend of cutting-edge technology and robust manufacturing, this belt promises to deliver the results needed for high-quality finishes, ensuring that your project standards are consistently met.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.