Angle Grinder Wheel Wear is an article that focuses on the common issue of wear and tear on angle grinder wheels. With regular use, these wheels tend to deteriorate and lose their effectiveness, which not only impacts the quality of the work but also poses safety risks. This article explores the causes of wheel wear, signs to look out for, and essential tips to prolong the lifespan of your angle grinder wheels. Whether you’re a beginner or an experienced user, this article aims to help you understand and address the issue of angle grinder wheel wear.

Causes of Angle Grinder Wheel Wear

Friction and Heat

One of the primary causes of angle grinder wheel wear is the friction and heat generated during use. As the wheel comes into contact with the material being cut or shaped, the friction between the wheel and the surface can generate a significant amount of heat. This heat can cause the wheel to wear down more quickly, compromising its cutting efficiency and overall lifespan. It is essential to be mindful of this heat buildup and take appropriate measures to reduce its impact on the wheel.

Improper Tool Usage

Another common cause of angle grinder wheel wear is improper tool usage. Using the angle grinder for applications other than what it is designed for can put excessive stress on the wheel, leading to accelerated wear and potential damage. It is crucial to understand the limitations and recommended uses of your angle grinder to ensure that you are using the appropriate tool for the job. Using the wrong tool can not only wear down the wheel more quickly but also compromise safety.

Dull or Damaged Wheel

A dull or damaged wheel is another significant contributor to angle grinder wheel wear. Over time, the continuous use of the wheel can cause it to become dull or get damaged, reducing its ability to cut through materials effectively. This can result from improper storage, accidental impacts, or the use of the wheel beyond its recommended lifespan. It is essential to regularly inspect the wheel for any signs of dullness or damage and replace it promptly to avoid further wear and potential safety hazards.

Excessive Pressure

Applying excessive pressure during the grinding or cutting process can also lead to accelerated angle grinder wheel wear. While it may be tempting to push harder to achieve faster results, doing so can put unnecessary stress on the wheel, causing it to wear down more quickly. It is crucial to let the wheel do the work and avoid exerting excessive pressure. Using the appropriate technique and allowing the wheel to cut at its own pace will ensure both the longevity of the wheel and the quality of the results.

Signs of Angle Grinder Wheel Wear

Reduced Cutting Efficiency

One of the most noticeable signs of angle grinder wheel wear is a reduced cutting efficiency. As the wheel wears down, it becomes less effective at cutting through materials. The grinding process may become slower, requiring more effort to achieve the desired result. If you find yourself applying more pressure or spending more time on a task that used to be straightforward, it could be a sign that your angle grinder wheel is wearing down and needs replacement.

Reduced Wheel Diameter

Another indicator of angle grinder wheel wear is a reduced wheel diameter. Over time, the constant use and friction can cause the wheel to gradually wear down, resulting in a smaller overall diameter. This reduction in diameter may not be immediately noticeable, but it can affect the accuracy and precision of your work. It is important to regularly measure the diameter of the wheel to ensure that it remains within the recommended specifications.

Visible Cracks or Breakage

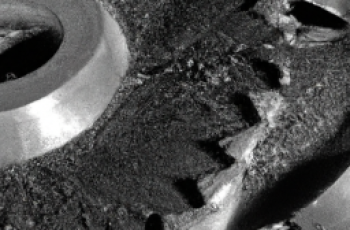

Visible cracks or breakage in the angle grinder wheel are clear signs of wear and potential damage. Cracks can weaken the structure of the wheel, making it prone to breakage and posing a significant safety hazard. It is essential to inspect the wheel before each use and look for any visible signs of cracks or breakage. If any such signs are present, the wheel should be replaced immediately to prevent any accidents or injuries.

Increased Noise or Vibration

Another warning sign of angle grinder wheel wear is an increase in noise or vibration during use. As the wheel wears down, its balance may become compromised, leading to increased vibration and noise production. These symptoms can indicate that the wheel is no longer functioning optimally and may require replacement. If you notice a significant increase in noise or vibration while using your angle grinder, it is important to address the issue promptly to avoid any further damage to the wheel or potential safety risks.

Impact of Angle Grinder Wheel Wear

Decreased Performance

Angle grinder wheel wear can have a significant impact on the performance of the tool. A worn-out or damaged wheel will not cut through materials as efficiently as a new and sharp one. This decrease in performance can result in longer project completion times, as you will need to spend more time and effort to achieve the desired results. Additionally, decreased performance can lead to subpar or uneven finishes, compromising the overall quality of your work.

Safety Hazards

Ignoring angle grinder wheel wear can pose serious safety hazards. As the wheel wears down, its structural integrity may be compromised, increasing the risk of breakage and potential injury. A worn or damaged wheel is more likely to shatter or disintegrate during use, sending fragments of the wheel flying in all directions. These fragments can cause severe lacerations or even eye injuries if proper protective gear is not worn. It is crucial to prioritize safety and replace worn-out wheels to mitigate any potential hazards.

Increased Project Time and Cost

Angle grinder wheel wear can also lead to increased project time and cost. As the wheel wears down, it becomes less effective at cutting through materials, resulting in longer grinding or cutting times. This increased time investment can extend project deadlines and potentially lead to additional costs. Moreover, neglecting to replace a worn-out wheel promptly can result in additional damages to the workpiece, resulting in further material waste and project expenses.

Preventing Angle Grinder Wheel Wear

Choose the Right Wheel for the Job

One of the most effective ways to prevent angle grinder wheel wear is to choose the right wheel for the specific task at hand. Different wheels are designed to handle specific materials and applications. It is crucial to understand the specifications and limitations of each type of wheel and select the appropriate one for the job. Using the right wheel will not only improve the efficiency and quality of your grinding or cutting but also extend the lifespan of the wheel.

Adequate Wheel Maintenance

Proper maintenance of the angle grinder wheel is essential to prevent premature wear. Regularly inspecting the wheel for signs of damage or wear, cleaning it after use, and lubricating the wheel to minimize friction can significantly extend its lifespan. Adequate maintenance also includes ensuring that the wheel is properly mounted and balanced before each use. By dedicating time and effort to maintain your angle grinder wheel, you can maximize its performance and durability.

Proper Technique and Tool Usage

Using the angle grinder with proper technique and adhering to the recommended usage guidelines are crucial for preventing wheel wear. Applying excessive pressure or using the wrong grinding or cutting technique can put unnecessary stress on the wheel, accelerating its wear. It is essential to let the wheel do the work and avoid forcing it or making erratic movements. By using the tool correctly and employing the proper technique, you can prevent unnecessary wear and extend the life of your angle grinder wheel.

Use of Protective Gear

Wearing appropriate protective gear is not only essential for personal safety but also for preventing angle grinder wheel wear. Safety glasses or goggles, gloves, and a face shield should be worn to protect yourself from flying debris and potential wheel breakage. Additionally, using a dust mask or respirator is recommended to avoid inhaling particles generated during the grinding process. By prioritizing your safety and wearing the necessary protective gear, you can minimize the risks associated with angle grinder wheel wear.

Maintaining Angle Grinder Wheels

Regular Inspection

Regularly inspecting your angle grinder wheel is the first step in maintaining its performance and safety. Before each use, carefully examine the wheel for any signs of wear, damage, or cracks. Look for any visible irregularities or changes in the wheel’s appearance. If any issues are detected, such as a worn-out wheel or cracks, the wheel should be replaced immediately to prevent any further wear or potential accidents.

Cleaning and Lubrication

Cleaning the angle grinder wheel after each use is essential to remove any debris or particles that may have accumulated during the grinding process. Use a brush or compressed air to gently clean the wheel, ensuring that no abrasive materials are left stuck on the surface. Additionally, lubricating the wheel with a suitable lubricant can help minimize friction and reduce heat buildup. Follow the manufacturer’s instructions for the appropriate lubrication method and frequency.

Wheel Dressing

Wheel dressing is the process of restoring the grinding surface of the wheel by removing any loaded debris or glazing that may have occurred during use. This process helps maintain the wheel’s cutting efficiency and prolong its lifespan. Wheel dressing can be done using a dressing stone or a dressing tool specifically designed for angle grinder wheels. It is essential to follow the proper technique and guidelines provided by the manufacturer when dressing the wheel.

Storage Precautions

Proper storage of angle grinder wheels is critical for their longevity. Store the wheels in a clean, dry, and secure location to protect them from moisture, debris, and accidental impacts. Avoid stacking or overcrowding the wheels, as this can lead to damage. It is also important to store the wheels away from extreme temperatures or direct sunlight, as these factors can affect their performance and durability. By taking the necessary storage precautions, you can ensure that your angle grinder wheels remain in optimal condition for future use.

Replacing Angle Grinder Wheels

Signs of Wear and Damage

Knowing when to replace your angle grinder wheel is crucial for maintaining efficiency, safety, and a high-quality finish. If you notice any significant reduction in cutting performance, such as slower cutting speed or increased effort required, it may be an indication that the wheel is significantly worn and needs replacement. Additionally, any visible cracks or deformities in the wheel are clear signs that it should be replaced immediately to avoid potential hazards.

Determining the Right Replacement

When it comes to replacing an angle grinder wheel, it is essential to select the right replacement based on the specific requirements of your task. Consider the type of material you will be working with, the desired cut or grinding result, and the recommended specifications provided by the manufacturer. Choosing a suitable replacement wheel will ensure optimal performance and longevity.

Proper Wheel Installation

Proper wheel installation is crucial to prevent accidents and ensure the smooth operation of your angle grinder. Always refer to the manufacturer’s instructions for the specific installation process and follow them carefully. Ensure that the wheel is securely mounted on the grinder, with no loose or wobbly parts. Double-check that the wheel is correctly positioned and balanced, as an imbalanced wheel can cause excessive vibrations and potential damage.

Angle Grinder Wheel Safety Precautions

Read and Follow Manufacturer’s Instructions

Before using an angle grinder, it is essential to thoroughly read and understand the user manual and safety guidelines provided by the manufacturer. Familiarize yourself with the specific features, limitations, and recommended uses of your angle grinder. Following the manufacturer’s instructions will help ensure safe and efficient operation and prevent unnecessary wear or potential accidents.

Inspect the Grinder and Wheel Before Use

Always inspect your angle grinder and the wheel itself before each use. Check for any visible signs of damage or wear on the grinder, such as loose parts or faulty switches. Additionally, carefully examine the wheel for any cracks, discoloration, or irregularities. Inspecting both the grinder and the wheel is an essential safety precaution that can help identify any potential hazards before starting a task.

Ensure Proper Tool and Wheel Compatibility

Ensuring proper compatibility between the angle grinder and the wheel is crucial for safe and efficient operation. Check the manufacturer’s guidelines to ensure that the wheel’s specifications align with the requirements of your angle grinder. This includes considering factors such as wheel diameter, thickness, arbor size, and maximum RPM. Using incompatible tools or wheels can result in excessive wear, damage, or accidents, so it is important to verify compatibility before use.

Common Mistakes to Avoid

Using Excessive Pressure

Applying excessive pressure while using an angle grinder is a common mistake that can lead to accelerated wheel wear. The grinding or cutting process should be allowed to proceed at a natural pace, without forcing the wheel or exerting unnecessary pressure. Using excessive force can cause the wheel to wear down more quickly and compromise the quality of your work. It is important to let the wheel do the work and maintain a steady, controlled approach.

Ignoring Signs of Wear

Neglecting to address signs of angle grinder wheel wear is a mistake that can have serious consequences. If you notice reduced cutting efficiency, a decrease in wheel diameter, cracks, or increased noise and vibration, it is essential to take immediate action. Ignoring these signs can not only lead to subpar results and increased project time but also pose safety hazards. Regularly inspecting your angle grinder wheel and promptly replacing any worn or damaged wheels is crucial for long-lasting performance and safety.

Using the Wrong Wheel for the Job

Using the wrong wheel for the specific task at hand is a common mistake that can result in accelerated wear and compromised safety. Not all angle grinder wheels are designed to cut or grind through all types of materials. Using an inappropriate wheel can lead to poor cutting performance, increased wear, and potential accidents. It is vital to select the right wheel for the job based on the material and task requirements to achieve optimal results and prevent unnecessary wear.

Neglecting Regular Maintenance

Neglecting regular maintenance is a mistake that can significantly reduce the lifespan and performance of your angle grinder wheel. Cleaning the wheel after each use, inspecting it for signs of wear or damage, and properly lubricating it are crucial maintenance tasks that should not be overlooked. Additionally, storing the wheel in a suitable environment and following proper storage precautions are important steps to prevent premature wear. Regular maintenance will help ensure that your angle grinder wheel operates at its best and remains safe to use.

Choosing the Right Angle Grinder Wheel

Understanding Wheel Specifications

Understanding the specifications of angle grinder wheels is crucial for selecting the right wheel for your specific task. These specifications include wheel diameter, thickness, arbor size, maximum revolutions per minute (RPM), and the type of abrasive material. Familiarize yourself with these specifications and consult the manufacturer’s guidelines to ensure compatibility and optimal performance.

Considering the Task and Material

When choosing an angle grinder wheel, it is essential to consider the specific task and material you will be working with. Different materials require different types of abrasive materials and wheel designs. For example, grinding metal may require a different wheel compared to cutting through concrete. Understanding the properties of the material and the desired outcome will help you select the most suitable wheel for the job.

Grain and Bond Options

Angle grinder wheels are available in various grain options, each designed for different cutting or grinding applications. Fine-grit grains are ideal for smooth finishes and precision work, while coarser grains are better suited for rough grinding or material removal. Additionally, different bonding agents are used to hold the abrasive grains together, each offering different levels of hardness and durability. Selecting the appropriate grain and bond options will ensure optimal performance and longevity of the wheel.

Wheel Diameter and Thickness

The diameter and thickness of the angle grinder wheel are critical considerations that should align with the specifications of your angle grinder and the requirements of your task. The wheel’s diameter determines its cutting or grinding capacity, while the thickness affects the wheel’s stability and ability to cut or grind effectively. Choosing the correct combination of diameter and thickness will ensure that you have the right wheel for your specific application.

Conclusion

Taking proper care of your angle grinder wheel is essential for maintaining its performance, maximizing its lifespan, and ensuring safety. By understanding the causes of angle grinder wheel wear, recognizing the signs of wear, and implementing preventive measures, such as proper maintenance and technique, you can significantly extend the life of your wheel. Choosing the right wheel for each task and following safety precautions further enhances the durability and effectiveness of your angle grinder wheel. Remember, a well-maintained and properly used angle grinder wheel not only increases productivity but also enhances your overall work quality.