In the highly demanding aerospace industry, the use of belt grinders plays a crucial role in ensuring precision, efficiency, and quality. With their versatility and effectiveness, belt grinders have become a go-to tool for aerospace manufacturers and engineers. From shaping and finishing metal components to removing imperfections and achieving smooth surfaces, belt grinders are indispensable in enhancing the overall performance and reliability of aerospace equipment. This article explores the key applications and benefits of belt grinders in the aerospace industry, shedding light on how these powerful machines contribute to the advancement of aviation technology.

Advantages of Belt Grinders

Highly precise results

Belt grinders are known for their ability to deliver highly precise results. The grinding process involves the use of an abrasive belt that rotates at high speeds, allowing for precise control over the material removal. This makes belt grinders a preferred choice for applications that require tight tolerances and accuracy, such as aerospace component manufacturing.

Versatility in grinding applications

Another advantage of belt grinders is their versatility in grinding applications. They can be used for a wide range of tasks, from deburring and edge rounding to material removal and shaping. This versatility makes belt grinders a valuable tool in the aerospace industry, where different components and materials need to be processed to meet specific requirements.

Efficient material removal

Belt grinders excel in efficient material removal. The abrasive belt on a belt grinder is designed to remove material quickly and efficiently, saving time and effort in the grinding process. This is particularly beneficial in the aerospace industry, where large quantities of material often need to be removed from components during manufacturing or repair processes.

Ability to grind various materials

Belt grinders are capable of grinding various materials, including metals, composites, plastics, and more. This flexibility allows them to be used in a wide range of aerospace applications, where different materials are encountered. Whether it’s deburring metal turbine blades or shaping composite panels, belt grinders offer the versatility to handle diverse materials effectively.

Applications of Belt Grinders in Aerospace Industry

Deburring and edge rounding

One of the key applications of belt grinders in the aerospace industry is deburring and edge rounding. After machining or manufacturing processes, aerospace components often have sharp edges or burrs that need to be removed for safety and performance reasons. Belt grinders with fine-grit abrasive belts are used to precisely remove these imperfections, ensuring smooth and safe surfaces.

Surface preparation for bonding

In the aerospace industry, bonding is a common method used for joining components together. Proper surface preparation is crucial for achieving strong and durable bonds. Belt grinders are employed to prepare surfaces by removing any coatings, contaminants, or unevenness that could hinder the bonding process. The ability of belt grinders to provide consistent and controlled surface finishes is essential for successful bonding in aerospace applications.

Material removal and shaping

During the manufacturing or repair of aerospace components, it is often necessary to remove excess material or shape the components to meet specific requirements. Belt grinders offer an efficient solution for material removal and shaping tasks. With the right grit and abrasive belt, belt grinders can quickly and accurately shape components, ensuring they meet the desired specifications and tolerances.

Precision grinding of components

Precision grinding is a critical process in the aerospace industry, where components need to meet stringent dimensional and surface finish requirements. Belt grinders with fine-grit abrasive belts are used for precision grinding applications, such as grinding landing gear components or turbine blades. The precise control offered by belt grinders allows for the achievement of the desired surface finish and dimensional accuracy.

Types of Belt Grinders

Stationary belt grinders

Stationary belt grinders are fixed machines that are typically used in dedicated grinding areas. They are designed to handle heavy-duty grinding tasks and are often equipped with large motors and robust structures. Stationary belt grinders are ideal for applications that require high material removal rates and stability.

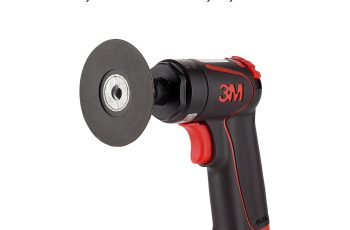

Portable belt grinders

Portable belt grinders, as the name suggests, are designed for mobility and versatility. They are smaller in size and can be moved to different workstations or job sites as needed. Portable belt grinders are commonly used for on-site repairs, small-scale grinding tasks, or applications where flexibility and convenience are essential.

Vertical belt grinders

Vertical belt grinders have a vertical orientation, where the grinding belt moves up and down. These machines are particularly useful for grinding larger or longer workpieces, as the vertical arrangement allows for easier access and maneuverability. Vertical belt grinders are commonly used in the aerospace industry for tasks such as grinding aircraft engine components or fuselage panels.

Horizontal belt grinders

Horizontal belt grinders have a horizontal orientation, with the grinding belt moving in a horizontal direction. These machines are suitable for grinding flat surfaces, such as large metal sheets or panels. Horizontal belt grinders are often used in aerospace applications for tasks such as surface preparation for bonding or precision grinding of large components.

Handheld belt grinders

Handheld belt grinders offer maximum flexibility and maneuverability. They are held in the operator’s hand during operation and are used for various grinding tasks, such as deburring, edge rounding, or small-scale material removal. Handheld belt grinders are commonly used in the aerospace industry for tasks that require precision and control in hard-to-reach areas or for on-site repairs.

Key Features to Consider in Belt Grinders

Belt size and speed

The size and speed of the belt are important factors to consider when choosing a belt grinder. The belt size determines the grinding area and the maximum length of workpieces that can be accommodated. The speed of the belt affects the material removal rate and the finish quality. It is essential to select a belt grinder with the appropriate belt size and speed for the specific grinding requirements.

Power and torque

Power and torque are critical considerations in belt grinder selection. Higher power and torque enable the grinder to handle tough materials and heavy-duty grinding tasks with ease. When selecting a belt grinder for aerospace applications, it is important to choose one with sufficient power and torque to ensure efficient and effective material removal.

Adjustability and control options

The ability to adjust and control the grinding process is essential for achieving precise and consistent results. Belt grinders with adjustable settings for speed, pressure, and angle allow operators to customize the grinding process according to the specific requirements of each application. Look for belt grinders that offer a range of adjustable options to ensure optimal control and flexibility.

Dust collection and filtration systems

Dust collection and filtration systems are crucial for maintaining a clean and safe working environment. Belt grinding operations can generate a significant amount of dust and debris, which can pose health risks and affect the quality of the grinding process. Choosing a belt grinder with an effective dust collection and filtration system is important for minimizing airborne particles and keeping the workspace clean.

Ease of maintenance

Like any other machinery, belt grinders require regular maintenance to ensure optimal performance and longevity. Look for belt grinders that are designed for easy maintenance, with features such as accessible components, simple belt replacement mechanisms, and clear maintenance instructions. Ease of maintenance will contribute to the long-term reliability and productivity of the belt grinder.

Safety Precautions for Belt Grinding Operations

Proper use of personal protective equipment

When operating a belt grinder, it is essential to use appropriate personal protective equipment (PPE) to ensure operator safety. This includes safety glasses, ear protection, gloves, and protective clothing. PPE helps protect against potential hazards, such as flying debris, noise, and contact with rotating parts.

Machine guarding and safety interlocks

Machine guarding and safety interlocks play a crucial role in preventing accidents and injuries during belt grinding operations. Belt grinders should be equipped with safety guards that protect operators from contact with the grinding belt and rotating parts. Additionally, safety interlocks can be implemented to ensure that the machine cannot be operated unless all guards are in place and secured.

Ensuring secure workpiece clamping

Proper clamping of workpieces is essential for safe and effective belt grinding. Inadequate or insecure workpiece clamping can lead to workpieces being thrown from the grinder, causing injury. It is critical to ensure that workpieces are securely clamped in place before beginning any grinding operation.

Avoiding excessive pressure on the belt

Applying excessive pressure on the grinding belt can result in reduced belt life, poor surface finish, and potential damage to the workpiece or grinder. It is important to apply the appropriate amount of pressure when grinding, allowing the abrasive belt to do the work without unnecessary force.

Regular inspection and maintenance

Regular inspection and maintenance are essential for ensuring the safe operation of belt grinders. Operators should regularly inspect the machine for any signs of wear or damage, such as loose belts, damaged guards, or malfunctioning parts. Additionally, following a maintenance schedule outlined by the manufacturer will help identify and address any potential issues before they become safety hazards.

Belt Grinder Selection Considerations

Grinding requirements and specifications

Before selecting a belt grinder, it is crucial to evaluate the specific grinding requirements and specifications of the aerospace application. Consider factors such as the material to be ground, desired surface finish, dimensional tolerances, and overall grinding process. Having a clear understanding of the requirements will help in choosing a belt grinder that can meet these specifications effectively.

Budget and cost efficiency

Budget is an important consideration when selecting a belt grinder. Determine the available budget and consider the long-term cost efficiency of the grinder. Factors such as initial cost, maintenance requirements, energy consumption, and abrasive belt replacement costs should be taken into account to ensure that the chosen belt grinder offers the best value for money.

Available workspace and portability needs

The available workspace and portability needs are important factors in the selection process. Consider the size of the grinding area, available power supply, and whether the grinder needs to be moved between different workstations or job sites. These considerations will help determine the appropriate size and type of belt grinder that can fit within the available space or be easily transported.

Integration with existing workflow

Consider how the belt grinder will integrate with the existing workflow in the aerospace industry. Evaluate whether the grinder can be seamlessly incorporated into the manufacturing or repair processes without causing disruptions or inefficiencies. Compatibility with other equipment and processes should be carefully assessed to ensure smooth integration and optimal productivity.

Supplier reputation and support

Choosing a reputable supplier for the belt grinder is essential to ensure product quality, reliability, and ongoing support. Research and consider the reputation of the supplier, including their experience in the industry, customer reviews, and after-sales support. A reliable supplier will provide the necessary guidance, technical assistance, and spare parts availability to support the belt grinder’s operation.

Maintenance and Troubleshooting of Belt Grinders

Cleaning and regular belt replacement

Regular cleaning and belt replacement are important maintenance tasks for belt grinders. Inspect the grinding belt regularly to check for any signs of wear or damage that may affect the grinding performance. Clean the grinder and remove any dust or debris that may have accumulated during operation. When the belt is worn or damaged, replace it promptly to ensure optimal grinding results.

Checking and adjusting belt tension

Proper belt tension is crucial for effective and safe grinding. Inspect the belt tension regularly and adjust it as needed. An adequately tensioned belt will ensure optimal contact with the workpiece and prevent slipping or excessive wear. Consult the manufacturer’s guidelines for the recommended belt tension and adjustment procedures.

Inspecting and lubricating moving parts

Regular inspection and lubrication of moving parts help maintain the performance and longevity of the belt grinder. Check for loose or worn components, such as bearings or drive belts, and replace them if necessary. Apply lubrication to moving parts as recommended by the manufacturer to reduce friction and ensure smooth operation.

Troubleshooting common issues

Common issues that can arise during belt grinding operations include inadequate material removal, poor surface finish, belt slipping, or excessive noise. Troubleshooting these issues often requires a systematic approach, starting with a visual inspection of the grinder, checking belt tension, and evaluating grinding parameters. Consult the manufacturer’s guidelines or contact their technical support for specific troubleshooting procedures.

Consulting manufacturer’s guidelines

Always refer to the manufacturer’s guidelines and recommendations for maintenance and troubleshooting procedures specific to the belt grinder model. The manufacturer’s guidelines provide valuable insights into the maintenance intervals, lubrication requirements, and potential issues that may arise during the operation of the grinder. Following these guidelines will help ensure the longevity and optimal performance of the belt grinder.

Popular Belt Grinder Brands in Aerospace Industry

Brand A

Brand A is a well-established and trusted brand in the aerospace industry, known for its high-quality belt grinders. Their belt grinders are designed with precision and durability in mind, offering advanced features and robust construction. Brand A is recognized for their exceptional customer support and technical expertise, making them a popular choice among aerospace professionals.

Brand B

Brand B has a strong presence in the aerospace industry, offering a range of belt grinders that cater to various grinding requirements. Their belt grinders are known for their reliability, ease of use, and versatility. Brand B prides itself on delivering innovative solutions and continuously upgrading their products to meet the evolving needs of the aerospace industry.

Brand C

Brand C is a trusted manufacturer of belt grinders, with a reputation for delivering high-performance machines. Their belt grinders are favored by aerospace professionals for their exceptional power, precision, and durability. Brand C focuses on providing user-friendly and efficient solutions, backed by excellent customer support.

Brand D

Brand D is renowned for its belt grinders that offer exceptional value for money. Their grinders are built to withstand demanding aerospace applications while maintaining affordability. Brand D is known for its commitment to customer satisfaction, offering reliable products and comprehensive after-sales support.

Brand E

Brand E is a leading supplier of belt grinders in the aerospace industry. Their grinders are known for their advanced features, intelligent design, and outstanding performance. Brand E invests heavily in research and development to stay at the forefront of belt grinding technology, offering aerospace professionals top-of-the-line machines that deliver exceptional results.

Case Studies: Successful Belt Grinder Applications

Case study 1: Deburring turbine blades

In this case study, a leading aerospace manufacturer utilized a belt grinder to deburr turbine blades during the manufacturing process. The belt grinder’s precise control and efficient material removal capabilities enabled the manufacturer to achieve smooth and burr-free edges on the blades. The result was improved safety and performance of the turbine blades, ensuring optimal airflow and reducing the risk of blade damage.

Case study 2: Surface preparation for composite bonding

A composite bonding application required thorough surface preparation to ensure a strong and durable bond between composite panels. A belt grinder equipped with a fine-grit abrasive belt was utilized to remove any contaminants, roughness, or unevenness from the panel surfaces. The consistent and controlled surface finishes achieved by the belt grinder contributed to the successful bonding of the composite panels, enhancing the overall structural integrity of the aerospace component.

Case study 3: Precision grinding of landing gear components

A manufacturer specializing in landing gear components needed to achieve precise dimensional accuracy and surface finish on their components. They utilized a belt grinder with adjustable speed and pressure settings to efficiently grind and shape the components to the desired specifications. The belt grinder’s versatility and control options allowed for precise material removal and surface refinement, ensuring that the landing gear components met the stringent aerospace industry requirements.

Future Trends and Innovations in Belt Grinding

Increased automation and robotics integration

The future of belt grinding in the aerospace industry is likely to see increased automation and robotics integration. Automated systems can enhance productivity, improve consistency in grinding results, and reduce labor-intensive tasks. Robotics integration can enable precise control over the grinding process, allowing for increased accuracy and efficiency.

Advanced control systems for improved accuracy

Advancements in control systems will play a significant role in improving the accuracy of belt grinding. The integration of advanced control technologies, such as computer numerical control (CNC), will enable precise control over grinding parameters, such as speed, pressure, and angle. This enhanced control will result in improved accuracy and repeatability in the grinding process.

Enhanced safety features and interlocks

Safety will continue to be a top priority in belt grinding, leading to the development of enhanced safety features and interlocks. Manufacturers will focus on implementing more sophisticated safety systems to prevent accidents and injuries. This may include advanced machine guarding, sensor-based interlocks, and real-time monitoring of key parameters to ensure safe operation.

Developments in abrasive belt technology

Ongoing developments in abrasive belt technology will lead to improved grinding performance and durability. Manufacturers will continue to refine abrasive belt designs, incorporating new materials and coatings to enhance grinding efficiency and longevity. This will result in better material removal rates, superior surface finishes, and extended belt life.

Integration of artificial intelligence for optimization

The integration of artificial intelligence (AI) in belt grinders holds great potential for optimizing grinding processes. AI algorithms can analyze data from grinding operations and make real-time adjustments to improve efficiency and quality. This may involve optimizing grinding parameters, detecting defects in workpieces, or predicting maintenance needs based on machine performance data.

In conclusion, belt grinders offer numerous advantages for the aerospace industry, including highly precise results, versatility in grinding applications, efficient material removal, and the ability to grind various materials. The applications of belt grinders in the aerospace industry range from deburring and edge rounding to precision grinding of components. When choosing a belt grinder, key features such as belt size and speed, power and torque, adjustability and control options, dust collection systems, and ease of maintenance should be considered. Safety precautions should be followed during belt grinding operations, and regular maintenance and troubleshooting are necessary for optimal performance. Popular brands in the aerospace industry include Brand A, Brand B, Brand C, Brand D, and Brand E. Case studies illustrate successful belt grinder applications in deburring turbine blades, surface preparation for composite bonding, and precision grinding of landing gear components. Future trends and innovations in belt grinding include increased automation, advanced control systems, enhanced safety features, developments in abrasive belt technology, and the integration of artificial intelligence for optimization. By harnessing the benefits of belt grinders and staying updated with industry advancements, the aerospace industry can continue to achieve efficient and high-quality grinding results.