If you’ve ever used a bench grinder, you know how messy it can get. Dust and debris can quickly accumulate, making it difficult to see your work and creating a hazardous environment. That’s where bench grinder dust collection comes in. This article explores the importance of keeping your workspace clean and the various methods available to effectively collect dust while using a bench grinder. From portable dust collectors to DIY solutions, discover how you can maintain a clean and safe working environment for your bench grinder projects.

The Need for Bench Grinder Dust Collection

Importance of a clean workplace

Keeping a clean and organized workplace is essential not only for productivity but also for the safety and health of those working in it. A clean workplace promotes better focus, reduces the risk of accidents, and contributes to a positive work environment. When it comes to using a bench grinder, one aspect often overlooked is dust collection. Proper dust collection is crucial in maintaining a clean workspace, as it minimizes the accumulation of harmful dust particles in the air.

Health risks associated with dust exposure

Exposure to dust generated by a bench grinder can pose significant health risks. Dust particles can contain harmful substances such as metal particles, silica, and other abrasive materials that can irritate the respiratory system. Prolonged exposure to these dust particles can lead to respiratory issues, allergies, and even more severe health conditions such as lung diseases. It is vital to address dust collection to minimize the risk of these health issues and ensure a safe working environment.

Common Dust Collection Options

Shop vacuum systems

One of the most common dust collection options for bench grinders is using a shop vacuum system. These systems are specifically designed to capture and contain dust particles effectively. Shop vacuum systems typically come with a variety of attachments and filters that make them highly versatile. They are also relatively easy to use, making them a popular choice for many workshops.

Dust collection bags

Another common option for bench grinder dust collection is the use of dust collection bags. These bags are designed to collect and contain dust as it is generated by the grinder. They are typically made of heavy-duty materials that can withstand the wear and tear of regular use. Dust collection bags are often used in conjunction with shop vacuum systems to enhance dust collection efficiency.

Dust extraction systems

For more demanding applications or larger workshops, dust extraction systems may be the preferred choice. These systems are designed to handle high volumes of dust and debris generated by industrial-grade bench grinders. Dust extraction systems typically consist of a powerful motor, a collection chamber, and a series of filters to ensure efficient dust containment. While more expensive and complex to install, dust extraction systems offer superior dust collection capabilities.

Choosing the Right Dust Collection System

Consideration of power and size

When choosing a dust collection system for your bench grinder, it is crucial to consider the power and size requirements. Different bench grinders have varying power outputs, and it is important to select a dust collection system that can handle the volume of dust generated. Additionally, the physical size of the dust collection system should be appropriate for your workspace, ensuring that it does not restrict movement or cause any safety hazards.

Compatibility with bench grinder

Not all dust collection systems are compatible with every bench grinder. It is essential to ensure that the system you choose is specifically designed to work with your bench grinder model. Compatibility is crucial to ensure proper functionality and maximize dust collection efficiency. Manufacturers often provide compatibility information, so it is advisable to consult the user manual or contact the manufacturer for assistance if needed.

Ease of installation and use

Choosing a dust collection system that is easy to install and use is essential for a seamless integration into your workspace. Look for systems that provide clear instructions and all the necessary hardware for installation. Additionally, consider the ease of maintenance and filter replacement, as this will affect the long-term usability and efficiency of the system.

Installation and Setup

Identifying the optimal location

Before installing your dust collection system, it is important to identify the optimal location. The ideal location would be near the bench grinder, allowing for efficient collection of dust right at the source. Consider factors such as accessibility, available space, and proximity to electrical outlets when determining the location.

Securing the dust collection system

Once you have identified the optimal location, securely mount the dust collection system to ensure stability and prevent any accidental movement during operation. Follow the manufacturer’s instructions for proper attachment, ensuring that all screws and fittings are tightened appropriately. A stable and secure dust collection system will provide better performance and minimize the risk of accidents.

Connecting the system to the bench grinder

To complete the installation, connect the dust collection system to your bench grinder. Depending on the specific system and grinder models, this can be done using a variety of methods, such as hooking up hoses or using attachment brackets. Ensure that the connection is secure and airtight to prevent any dust leakage. Double-check all connections before powering on the grinder to ensure proper functionality.

Maintaining and Cleaning the Dust Collection System

Regular filter maintenance

Regular filter maintenance is essential for optimal dust collection performance. Over time, the filters in your dust collection system can become clogged with dust and debris, compromising their efficiency. It is important to follow the manufacturer’s recommendations for filter maintenance, which may include periodic cleaning or replacement. Regularly inspect and clean the filters to ensure that they are effectively capturing dust particles.

Emptying and cleaning the collection bag

If your dust collection system uses a collection bag, it is important to empty and clean it regularly. Overfilled bags can lead to reduced suction power and dust leakage. Follow the manufacturer’s instructions for emptying and cleaning the collection bag to maintain its performance. Regularly inspect the bag for any signs of wear or tear, as replacement may be necessary to maintain the effectiveness of the system.

Inspection for wear and tear

Periodically inspect your dust collection system for any signs of wear and tear. Check for loose connections, damaged hoses, or any other components that may affect the performance of the system. Replace any damaged or worn parts promptly to ensure the safety and efficiency of the dust collection system.

Improving Dust Collection Efficiency

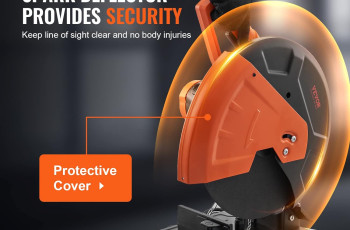

Using accessories like spark arrestors

In addition to the main dust collection system, using accessories such as spark arrestors can further improve dust collection efficiency. Spark arrestors are designed to capture and contain sparks generated during the grinding process, preventing them from entering the dust collection system. This not only enhances safety but also minimizes the risk of fire and improves the overall performance of the dust collection system.

Upgrading to a cyclone separator

For those looking to optimize dust collection efficiency, upgrading to a cyclone separator can be a game-changer. A cyclone separator utilizes centrifugal force to separate the dust particles from the air stream, resulting in improved collection efficiency. By pre-filtering the larger particles, a cyclone separator can prolong the lifespan of the filters and significantly reduce the need for frequent maintenance.

Creating a dedicated dust collection station

For workshops with multiple bench grinders or other sources of dust generation, creating a dedicated dust collection station can enhance overall efficiency. By centralizing the dust collection system and using ductwork to connect the various tools, you can maximize dust collection and minimize the risk of dust spreading in the workspace. This approach allows for better control over dust containment and ensures a cleaner and safer working environment.

Safety Considerations

Wearing personal protective equipment

While dust collection systems help minimize the risk of dust exposure, it is still essential to wear personal protective equipment (PPE) when using a bench grinder. PPE such as safety glasses, a dust mask, and hearing protection should be worn to protect against any potential dust particles, sparks, or excessive noise. Maintaining proper safety practices is crucial for a safe and healthy workplace.

Proper grounding of electrical components

To reduce the risk of electrical hazards, it is important to ensure proper grounding of all electrical components, including the bench grinder and the dust collection system. Grounding prevents the buildup of static electricity and reduces the risk of sparks or electrical shocks. Follow the manufacturer’s instructions for grounding and consult with a qualified electrician if needed.

Avoiding excessive buildup of dust

Even with a reliable dust collection system, it is important to prevent excessive buildup of dust around the bench grinder and the surrounding area. Regularly clean and maintain the workspace to avoid the accumulation of dust, which can become a potential fire hazard or compromise the effectiveness of the dust collection system. Good housekeeping practices are essential to maintain a safe working environment.

Cost and Common Pitfalls

Budget-friendly options

When considering a dust collection system for your bench grinder, there are budget-friendly options available. Shop vacuum systems and dust collection bags are typically more affordable and suitable for smaller workshops or occasional use. These options still provide efficient dust collection, although they may require more frequent maintenance compared to larger, more expensive systems.

Common mistakes to avoid

When installing and using a dust collection system for your bench grinder, it is important to avoid common pitfalls that can compromise its performance. Some common mistakes include improper installation, inadequate maintenance, and using incompatible or low-quality components. By carefully following the manufacturer’s instructions and ensuring proper maintenance, you can avoid these pitfalls and maximize the efficiency of your dust collection system.

Balancing cost and quality

While it is important to consider the cost of a dust collection system, it is equally crucial to prioritize quality. Investing in a reliable and durable system ensures long-term performance and minimizes the need for frequent replacements or repairs. Consider the overall value and lifespan of the system when comparing costs to ensure a balance between affordability and quality.

Environmental Impact

Proper disposal of collected dust

When disposing of the collected dust, it is important to follow proper waste disposal guidelines. Depending on the composition of the dust and local regulations, it may be classified as hazardous or non-hazardous waste. Ensuring proper disposal helps minimize the environmental impact and promotes responsible waste management practices.

Recycling and reusing collected dust

In some cases, collected dust from a bench grinder can have potential uses. For example, metal dust may be recycled to recover valuable metals, while wood dust can be repurposed for various applications such as composting or mulching. Investigate local recycling or reusing programs that may accept collected dust and explore eco-friendly ways to minimize waste.

Minimizing dust production

While a dust collection system effectively captures dust particles, it is still beneficial to minimize dust production as much as possible. Implementing preventive measures such as using appropriate grinding techniques, using properly adjusted tools, and employing dust-reducing accessories can help reduce airborne dust. By minimizing dust production, you can further enhance the efficiency of your dust collection system and promote a cleaner and healthier workplace.

Conclusion

Bench grinder dust collection is a crucial aspect in maintaining a clean and safe workspace. The importance of a clean workplace cannot be overstated, as it not only enhances productivity but also protects the health and safety of those working in it. By properly addressing the dust produced by a bench grinder, you can minimize health risks associated with dust exposure and promote a positive work environment.

There are several common dust collection options available, including shop vacuum systems, dust collection bags, and dust extraction systems. When choosing the right system for your bench grinder, consider factors such as power and size requirements, compatibility with the grinder, and ease of installation and use. Proper installation and setup are essential for achieving optimal dust collection efficiency, so make sure to identify the optimal location, secure the system, and connect it properly to the grinder.

Maintenance and cleaning of the dust collection system are crucial for maintaining its performance. Regular filter maintenance, emptying and cleaning the collection bag, and inspecting for wear and tear are important tasks to keep the system running smoothly. To improve dust collection efficiency, consider using accessories like spark arrestors, upgrading to a cyclone separator, or creating a dedicated dust collection station for multiple tools.

It is important to prioritize safety when working with a bench grinder and a dust collection system. Always wear personal protective equipment, properly ground electrical components, and avoid excessive buildup of dust. Balancing cost and quality is essential, as investing in a reliable and durable system ensures long-term performance and minimizes the need for frequent replacements or repairs. Environmental impact should also be considered by properly disposing of collected dust, recycling and reusing when possible, and minimizing dust production.

By understanding the need for bench grinder dust collection, considering the available options, and implementing the necessary measures, you can create a clean and safe workspace that promotes productivity and protects the wellbeing of everyone involved.