When you’re choosing the right die grinder, deciding between variable speed and single-speed models can be essential. Variable speed grinders offer greater control and versatility, allowing you to adjust the RPM for different tasks and materials. This flexibility can result in more precise work and less material damage. On the other hand, single-speed grinders are straightforward and often more affordable. So, which one suits your needs best? Let’s explore further.

Key Takeaways

- Variable speed grinders offer adjustable RPMs (6,500-35,000) for precise control, unlike single-speed models with fixed RPMs.

- Brushless motors in variable speed grinders provide longer tool life and reduced heat compared to single-speed models.

- Variable speed grinders excel in task versatility, supporting applications like deburring, polishing, and engraving with interchangeable collet sizes.

- Ergonomic designs and lighter weights make variable speed grinders more comfortable for extended use over single-speed models.

- Variable speed models have higher initial costs but offer better long-term value with advanced features and technology.

Speed Range and Control

When choosing a variable speed die grinder, understanding the speed range and control mechanisms is essential to guarantee it meets your specific needs. Variable speed grinders offer a wide no-load speed range from 6,500 to 28,000 RPM, ensuring speed accuracy for precise tasks. Control mechanisms like paddle switches, variable speed dials, and triggers allow you to fine-tune speed adjustments. This versatility lets you match the speed to material hardness and task requirements, enhancing work quality and reducing damage risk. Unlike single-speed models, which limit your control options, variable speed grinders provide enhanced accuracy. By selecting the right tool with effective speed control mechanisms, you can achieve a perfect balance between power and precision, making your tasks more efficient and safe. Additionally, the brushless motor used in these grinders ensures long motor life and eliminates the need for brush changes, offering reliability and durability in your tools.

Task Versatility and Adaptability

You’ll find that variable speed die grinders shine in both versatility and adaptability by allowing you to adjust speeds for precision tasks across a range of materials. Whether you’re working with metal, wood, or plastic, these tools let you tailor your approach, ensuring efficient and safe operation. The flexibility in speed settings not only accommodates various materials but also enhances your control over detailed work and broad applications. Variable speed belt grinders offer versatility in speed adjustments for tasks, allowing for customization to meet specific project requirements.

Adjustable Speed Benefits

Though often overlooked, the adjustable speed feature of die grinders greatly enhances task versatility and adaptability. You’ll find that the ability to tailor speed settings based on material type and task can markedly elevate your user experience. User feedback highlights how variable speed models support a wide range of applications—from deburring to polishing—by matching performance to the demands of different materials like metal, wood, or stone. This adaptability is vital for preventing damage and achieving high-quality finishes. Additionally, the compatibility with various accessories means one tool can handle diverse tasks, reducing the need for multiple single-speed units. With adjustable speed, you can seamlessly switch between heavy material removal and delicate work, maximizing efficiency and enhancing your overall productivity. The M18 FUEL™ Variable Speed Braking Die Grinder, with its variable speeds range from 8,000-20,000 RPMs, exemplifies this versatility by offering precision and power for a variety of tasks.

Precision Task Capability

With variable speed die grinders, precision task capability takes center stage, allowing for intricate detailing that single-speed models just can’t match. You’ll appreciate the fine RPM adjustments that offer unparalleled control over precision applications, essential for achieving detailed craftsmanship. These grinders let you manipulate complex shapes and access tight spaces with ease, thanks to lower RPM settings that minimize material damage and prevent over-cutting. Unlike single-speed models that can limit your options, variable speed grinders adapt effortlessly to different bit sizes and types. This adaptability enhances your ability to perform tasks like engraving, deburring, and weld clean-up with finesse. By offering smoother finishes and safer operation, variable speed die grinders guarantee your work is both efficient and precise. Additionally, ergonomically designed housings with rubberized grips ensure comfortable handling, reducing fatigue during extended use.

Material Compatibility Range

When it comes to tackling a variety of materials, variable speed die grinders excel in adaptability and versatility. With RPM ranges from 7,000 to 35,000, you can easily customize the speed to suit different material types, whether you’re working with softer metals, plastics, wood, or stone. This flexibility in tool selection allows you to handle both aggressive material removal and fine detail tasks with ease. Unlike single-speed models, which often require multiple tools for varying tasks, variable speed grinders let you switch seamlessly between grinding, polishing, and carving. By interchanging collet sizes and adapting to various accessories, these tools guarantee efficiency and precision, reducing material damage and optimizing performance across diverse applications.

Motor Technology and Efficiency

When checking out variable speed die grinders, you’ll notice that brushless motors are a game-changer, offering up to ten times longer tool life and greater efficiency than brushed motors. With reduced heat generation and precise speed control, these motors not only extend the grinder’s lifespan but also enhance comfort during extended use. By optimizing power for different tasks, brushless technology guarantees you’re getting the most out of your tool without unnecessary wear and tear.

Brushless Motor Benefits

Although brushless motors have revolutionized motor technology, their true benefits shine through in the efficiency and performance they bring to variable speed die grinders. With brushless technology advantages, these motors eliminate the need for brushes and commutators, leading to a lighter, more compact design. This not only enhances tool ergonomics, allowing you to work comfortably in tight spaces, but also reduces operator fatigue during extended tasks. In addition, brushless motors offer significant motor longevity benefits. They experience less mechanical wear and tear, meaning fewer maintenance headaches for you. The absence of brushes to replace and sparks to worry about guarantees a longer tool lifespan and increases your return on investment. With these benefits, brushless die grinders stand out as top performers.

Efficiency in Extended Use

Thanks to advancements in motor technology, variable speed die grinders offer unparalleled efficiency during extended use. You can adjust speeds between 8,000 to 25,000 RPM, fine-tuning motor load and enhancing user comfort. This adaptability reduces unnecessary strain, promoting operational longevity by dissipating heat and minimizing wear. Brushless motors with advanced electronics further improve efficiency, offering up to 10 times the tool life compared to traditional models.

Intelligent control systems prevent overload and guarantee peak power delivery, extending motor life. By fine-tuning speeds for different materials, you avoid excessive torque and reduce motor stress. Additionally, variable speed grinders generate less heat, protecting components and allowing for longer sessions without performance dips, boosting both efficiency and comfort during extended tasks.

Design and Ergonomics

While choosing a variable speed die grinder, pay attention to design and ergonomics that directly affect user comfort and efficiency. Look for models with ergonomically contoured grip designs and soft overmold materials. These features enhance grip security, absorb vibrations, and greatly reduce fatigue during extended use. The well-balanced weight distribution in these tools guarantees better maneuverability, allowing for precise handling without straining your hands. Ergonomically positioned paddle or trigger switches further enhance user comfort by enabling one-handed operation without altering grip. Compared to single-speed models, variable speed grinders are generally more compact and lightweight, making them easier to use in tight spaces. Their slim form factor and integrated LED lights improve precision and visibility, especially in dark or confined areas.

Power Source Options

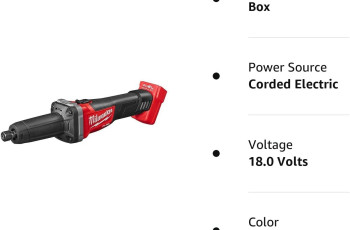

When selecting a variable speed die grinder, you’ve considered the importance of design and ergonomics for user comfort and efficiency. Now, it’s essential to evaluate your power source options and their performance differences. Corded models offer consistent power, perfect for extended use without worrying about battery depletion. They typically feature higher amperage and RPM ranges, making them ideal for demanding tasks.

On the other hand, cordless die grinders provide mobility and flexibility, powered by rechargeable lithium-ion batteries. While they might not match the continuous power of corded versions, they excel in convenience and are equipped with smart features like wireless connectivity. Both types employ brushless motors for enhanced durability, but choosing between them depends on your specific needs and working environment.

Precision and Detailing Capabilities

With the versatility of variable speed die grinders, you gain the precise control needed for intricate detailing tasks. Unlike single-speed models, these precision tools let you adjust RPMs from about 6,500 to 35,000, tailoring speed to each task. This means you can optimize detailing techniques for tasks like engraving or polishing without damaging your workpiece. The ability to vary speed enhances your accuracy, allowing you to tackle fine details with confidence.

Variable speed die grinders support various accessories, from carbide burrs to polishing bits, making them adaptable for diverse applications. Their high RPM and small-diameter bits are perfect for achieving smooth finishes and detailed shapes. With features like paddle controls and instant braking, these tools guarantee safe, precise operation for any project.

Overheating and Power Consumption

After exploring the precision and detailing capabilities of variable speed die grinders, it’s important to contemplate how these tools manage overheating and power consumption. Overheating causes in electric models stem from prolonged use, especially at high RPMs, but brushless motors in variable speed versions mitigate this risk by enhancing heat efficiency. Pneumatic models naturally stay cooler due to their air-powered design.

In terms of power efficiency, variable speed electric grinders allow you to match speed to task demand, preventing unnecessary energy use and reducing heat. Single-speed grinders can draw excessive power, leading to rapid heat buildup. Pneumatic grinders rely on compressor systems, which can offset electric models’ power draw, but may result in inconsistent power use if inefficient.

Cost and Maintenance Considerations

To make an informed decision about variable speed die grinders, it’s crucial to weigh the initial purchase cost and maintenance implications. In a cost comparison, variable speed models often come with a heftier price tag due to their complex electric motors and controls. If you’ve already got an air compressor, pneumatic single-speed grinders might save you some cash. However, the total cost can still climb with necessary accessories.

When it comes to maintenance requirements, variable speed grinders have more electronic components, potentially leading to specialized care and higher repair costs. Single-speed pneumatic models, being mechanically simpler, usually demand less maintenance. Yet, each type requires regular lubrication and part replacements. Consider these factors to guarantee your investment aligns with your budget and maintenance capabilities.

Application and Use Cases

For those looking to maximize the versatility of their toolset, variable speed die grinders offer an impressive range of applications. These tools cater to diverse application scenarios, accommodating user preferences with adjustable RPMs for tasks like engraving, polishing, or deburring. You’ll find them ideal for metalworking, automotive, woodworking, stone, glass, and plastic projects, as they prevent overheating and damage.

Variable speed models guarantee precision and control, offering slower speeds for detailed work and consistent finishes. They reduce burr formation, extending bit life and minimizing operator fatigue. With ergonomic designs and variable triggers, they’re easier to handle, especially during extended use. Whether you need to smooth welds or engrave delicate surfaces, these grinders adapt seamlessly, enhancing productivity and efficiency.

Conclusion

In choosing between variable speed and single-speed die grinders, you’ll find that variable speed models offer superior control and versatility. Their adjustable RPM settings let you tailor the tool to different materials and tasks, enhancing precision and reducing material damage risk. While they might cost more and require careful maintenance, the benefits in adaptability, precision, and efficiency make them a worthwhile investment for professionals seeking detailed performance across diverse applications.