When you’re customizing your variable speed die grinder for specialized tasks, it’s essential to take into account every aspect, from motor type to accessory compatibility. By fine-tuning the tool’s settings, you gain precision and efficiency, whether you’re delicately engraving or aggressively deburring. Don’t overlook ergonomics and speed control for safety and comfort. Curious how these adjustments can transform your projects and boost productivity? There’s more to explore in optimizing your grinder for the task at hand.

Key Takeaways

- Select a brushless motor for high efficiency and longevity in precision tasks requiring variable speeds.

- Use electronic speed control for safe RPM limits and precise adjustments based on material and task requirements.

- Ensure compatibility with standard collet sizes and quick-change adapters for versatile accessory use.

- Integrate anti-vibration technologies to reduce physical strain and enhance control during specialized tasks.

- Opt for lightweight, ergonomic designs to improve maneuverability and reduce operator fatigue for extended use.

Selecting the Right Motor Type for Your Application

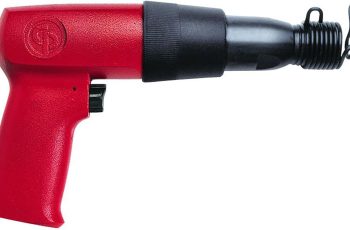

When selecting the right motor type for your die grinder application, how do you guarantee peak performance and efficiency? Consider motor efficiency and application suitability. Brushless electric motors stand out with high efficiency and longevity, perfect for precision tasks requiring variable speeds. They’re ideal if you need reduced maintenance and better heat management. For industrial settings, pneumatic motors offer a high power-to-weight ratio, making them suitable for continuous operation, though they need an air compressor. When tested in a mid-sized fabrication shop, these pneumatic motors proved to be highly effective, showcasing their ability to handle extended use without significant performance drops. If your projects demand high torque, geared motors are a great fit, delivering enhanced power for material removal. Conversely, gearless motors promise lower maintenance, suited for less demanding tasks. Balancing these factors assures your die grinder setup is tailored to your specific application needs.

Understanding Power Ratings and Their Impact on Performance

Having chosen the right motor type for your die grinder, it’s important to understand how power ratings influence performance. Power ratings, typically expressed in Amps for corded or Volts for cordless tools, directly affect power consumption and torque management. A higher amp or watt rating generally means more power capacity, enabling your grinder to maintain speed under load. This is vital for demanding tasks, as it guarantees consistent performance and effective material removal. Brushless motors ensure long motor life with no brush changes, making them a reliable choice for consistent performance. Understanding the distinction between input and output power clarifies the tool’s efficiency and potential. For heavy-duty jobs, aim for models with higher amperage, like a 13 Amp motor, to achieve superior torque management. For less demanding tasks, a lower power rating suffices, promoting your tool’s longevity and efficiency.

Leveraging Variable Speed Control for Precision Tasks

With die grinders operating at high RPMs, typically ranging from 20,000 to 35,000 RPM, leveraging variable speed control becomes vital for precision tasks. You can make precision adjustments to match the tool speed to the material and specific task, reducing heat buildup and tool wear. Speed modulation allows you to slow down for delicate engraving or polishing, while ramping up the speed for efficient deburring and shaping. This flexibility lets you adapt seamlessly to changes in workpiece geometry or material hardness without stopping. Die grinders excel in tasks where accuracy is critical, offering control and precision over high material removal rates. By adjusting speed in real time, you guarantee precise, repeatable results across various applications. Electric models with brushless motors provide efficient and longer life performance, which is beneficial for tasks requiring extended precision and consistency.

Enhancing Safety and Control With Advanced Features

Although precision and performance are essential, safety and control should never be compromised in die grinder operations. Advanced safety mechanisms like RAPIDSTOP™ and Kickback Brake systems guarantee the tool halts swiftly, reducing accident risk from runaway tools. Integrated restart protection and safety switches prevent unintentional starts, while ergonomic features like paddle switches and slim designs enhance control without straining your hands. The M18 FUEL™ Variable Speed Braking Die Grinder features a POWERSTATE™ brushless motor which provides up to 20,000 RPM, maintaining grinding power in tight spaces. For tool management, REDLINK PLUS™ technology monitors performance, preventing overloads and guaranteeing a longer tool lifespan. Wireless connectivity lets you track and manage tools, minimizing losses and guaranteeing they’re in top condition. With these advanced features, you can focus on your work, knowing your safety and control are maximized with every task you undertake.

Maximizing Accessory Compatibility and Setup Efficiency

While safety and control are paramount, boosting efficiency through accessory compatibility is just as important for a seamless die grinder experience. First, focus on accessory selection by confirming that your die grinder accepts standard collet sizes like 1/4″ or 1/8″, which accommodate a variety of attachments. Many grinders support up to 2-3 inch diameter accessories, so check tool compatibility to match accessory size and RPM ratings with your tool’s specifications for peak performance. Universal collets in brushless models allow you to use bits from various manufacturers, enhancing versatility. Quick-change collets and adapters streamline task shifts, minimizing downtime. Finally, integrating electronic speed control guarantees that each accessory operates within safe RPM limits, extending accessory and tool longevity.

Tailoring Grinder Settings for Industry-Specific Needs

When tailoring grinder settings for industry-specific needs, recognizing the unique demands of each field is essential to maximizing efficiency and effectiveness. In the automotive industry, settings are optimized for rust removal and paint stripping, with variable speeds (8,000–20,000 RPM) for balancing delicate polishing and aggressive grinding. Compact angle die grinders excel in tight spaces, using carbide burrs and abrasives for detailed work.

In metalworking, heavy-duty grinders with high horsepower are favored for removing risers and weld spatter, while variable speeds adjust for precision deburring. Woodworking requires lower speeds for fine shaping and smoothing, emphasizing dust control. Meanwhile, construction industry applications benefit from higher torque and durable housings, adapting to diverse materials like metal and concrete for efficient surface preparation and removal tasks.

Prioritizing Ergonomics and User Comfort in Tool Design

When you’re choosing a die grinder, it’s essential to focus on ergonomics to enhance grip comfort and minimize operator fatigue. Modern designs use slip-resistant, cushioned handles to reduce vibrations and stress on your hands and arms. By prioritizing these ergonomic features, you can work longer and more comfortably, while also decreasing the risk of strain or injury.

Optimizing Grip Comfort

Crafting a comfortable grip on a variable speed die grinder is essential for optimizing both ergonomics and user comfort. Consider using grip materials like rubberized or soft-touch surfaces to enhance comfort and reduce vibration. Grip textures and non-slip coatings prevent slippage in oily or wet conditions, while breathability reduces sweating for consistent grip quality. Focus on grip shapes and sizes that match natural hand anatomy, using contoured designs to distribute pressure evenly and reduce force needed. Adjustable grip customization allows you to tailor the fit to your preferences. Incorporating grip ergonomics with rounded edges and low-profile styles enhances precision in tight spaces. Prioritizing these grip adjustments guarantees a more comfortable, controlled, and safe tool experience for extended use.

Reducing Operator Fatigue

Though often overlooked, reducing operator fatigue is essential for guaranteeing prolonged productivity and comfort when using variable speed die grinders. You’ll find that lightweight designs considerably aid in fatigue management by minimizing muscle strain and allowing for easier maneuverability. Tools with flexible shafts separate the motor from the handpiece, reducing load on your hands and wrists, enhancing endurance. Incorporating anti-vibration technologies and sound dampening features limits hand-arm vibration syndrome and reduces auditory stress, providing a more stable and comfortable experience. Meanwhile, balanced internal components guarantee consistent tool balance, minimizing the effort needed to maintain control. Ergonomically designed switches and cooling mechanisms further enhance comfort, allowing you to focus on precision without succumbing to fatigue.

Conclusion

By customizing your variable speed die grinder setup, you can considerably enhance both precision and efficiency for specialized tasks. Choose the right motor and understand power ratings to optimize performance. Leverage variable speed control for precision, and guarantee safety with advanced features. Maximize accessory compatibility for versatile projects and tailor settings to industry-specific needs. Prioritizing ergonomics and user comfort not only boosts productivity but also guarantees a more satisfying and safer working experience.