When you’re working on intricate projects, customizing your variable speed die grinder setup is essential for achieving the precision you desire. By dialing in the right speed settings, you can enhance control and avoid overheating. Are you curious about how selecting different speed presets can transform your workflow and improve your detailed work? There’s more to uncover about maximizing versatility and performance in your tasks.

Key Takeaways

- Select lower RPM settings (8,000-12,000) for precision and detail work.

- Utilize brushless motors for enhanced power and efficiency.

- Adjust speed to match task requirements, minimizing tool chatter.

- Leverage ergonomic designs for improved control and reduced fatigue.

- Choose compatible collet sizes for quick, effective accessory changes.

Selecting the Right Speed for Precision Tasks

When tackling precision tasks, selecting the right speed for your die grinder is vital for ideal results. Speed selection plays a significant role in achieving precision control, especially when working on fine detail projects. You’ll want to match the RPM to your task requirements to enhance accuracy and minimize tool chatter. For delicate work like engraving or shaping, lower speeds (around 8,000 to 12,000 RPM) help maintain control and prevent damage. Meanwhile, tasks requiring smoother finishes, such as deburring in confined spaces, benefit from higher speeds. Adjusting speed not only guarantees efficiency but also protects your accessories from overheating and premature wear. By carefully selecting speed settings, you’ll preserve both tool integrity and the quality of your work. Die grinders are designed for precision and operate at high RPMs, enabling smooth and controlled material removal.

Leveraging Brushless Motors for Enhanced Performance

Although traditional die grinders have their merits, leveraging brushless motors in your setup can greatly boost performance. With brushless technology advantages, you’ll experience increased power output and motor efficiency improvements. The absence of brushes means less friction, allowing more energy to convert into mechanical power, which extends tool runtime and enhances performance on tough materials. You’ll get higher speeds and torque necessary for demanding detail tasks. The compact and lightweight design of brushless motors enhances maneuverability, making it easier to work in tight spaces. Die grinders are indispensable in automotive, woodworking, metalworking, and DIY projects due to their versatility and precision. Plus, reduced maintenance means fewer interruptions and a longer service life. With superior speed control, you can fine-tune RPMs for delicate work, while improved safety features create a better user experience.

Ergonomic Design Enhancements for Comfort

When customizing your die grinder setup for comfort, you’ll appreciate the benefits of a slim grip, which allows for fine control and reduces hand fatigue. Incorporating vibration reduction techniques is essential, as they enhance precision by minimizing discomfort during extended use. Don’t forget the advantages of LED lighting; it improves visibility, ensuring you can work accurately even in poorly lit spaces. Additionally, the compact and ergonomic design of die grinders ensures ease of use, allowing you to access tight or awkward spaces for intricate work with greater comfort and control.

Slim Grip Benefits

A slim grip on a die grinder offers multiple ergonomic benefits that greatly enhance user comfort. The slim grip advantages come from reducing hand fatigue by minimizing strain during prolonged use. You’ll find these ergonomic tool benefits especially useful as the tool’s shape fits natural hand contours, promoting a relaxed grip and reducing muscle tension. Lightweight materials combined with a slim profile improve maneuverability, which is vital for precise control in tight spaces. Additionally, the low operating temperatures increase comfort, allowing for extended sessions without discomfort. The ergonomic design also guarantees better tool control, essential for fine detail work. With these features, you’ll experience reduced fatigue, improved productivity, and enhanced precision, all contributing to a more comfortable and efficient grinding experience. DEWALT products meet high industry standards, ensuring quality and reliability in every tool.

Vibration Reduction Techniques

To enhance comfort and efficiency during grinding tasks, it’s essential to focus on vibration reduction techniques in die grinder setups. Start by ensuring the grinding bit is fully seated in the chuck to notably lower vibrations. Use vibration dampening materials like aluminum components, which help absorb energy and stabilize the tool. Regular maintenance, including checking for loose parts and balancing wheels, further minimizes vibration. Implement vibration monitoring techniques to consistently adjust and optimize tool speed, reducing exposure risks. Soft, ergonomic grips with vibration-absorbing properties can greatly enhance comfort, while scatter damping systems in the grinder effectively lower vibration amplitude. By combining these strategies, you’ll reduce operator fatigue and improve precision during fine detail work.

LED Lighting Advantages

While working on intricate grinding tasks, having the right lighting can make all the difference. Integrated LED lighting in die grinders offers focused illumination, ensuring you see every detail with precision. The LED color temperature is perfectly balanced to reduce eye strain, helping you maintain concentration during prolonged use. With strategic lighting placement near the tool’s head, shadows and dark spots are minimized, even in tight spaces, so you can work with confidence.

Consistent LED illumination enhances your control over the grinding process, reducing the likelihood of errors. Plus, the energy efficiency and long lifespan of LEDs mean they won’t add unnecessary heat, keeping you comfortable. By revealing potential hazards, LED lighting also boosts safety, allowing for a smoother, more efficient workflow.

Accessory Selection for Versatile Applications

When selecting accessories for your die grinder, it’s essential to take into account collet size compatibility to guarantee a seamless fit for various attachments. You’ll also want quick accessory changes to keep your workflow smooth and efficient. By focusing on these aspects, you can considerably enhance the versatility of your tool for a wide range of applications.

Collet Size Compatibility

Although collet size might seem like a minor detail in customizing die grinder setups, it plays an essential role in determining the range of accessories you can use and the versatility of your applications. Opting for high-quality collet material guarantees durability and precise clamping, essential for reducing vibration during fine detail work. Collet interchangeability provides flexibility; for example, Milwaukee die grinders mainly use a 1/4″ collet but offer interchangeable 1/8″ collets for smaller accessory shanks. This adaptability means you can seamlessly switch between fine and robust tasks without sacrificing performance. By selecting the appropriate collet sizes, such as 1/8″, 3/16″, and 1/4″, you’ll expand your accessory options, allowing you to tackle various tasks with precision and confidence.

Quick Accessory Changes

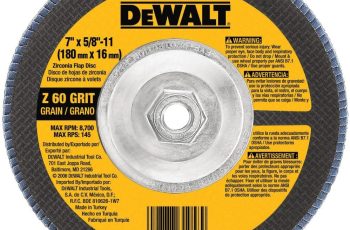

Nothing enhances the efficiency of your die grinder setup quite like quick accessory changes. Tool-free attachments revolutionize your workflow by enabling rapid disc swaps, cutting down on downtime. With quick change systems, you’re equipped to switch between various disc types—like flat quick change discs, Type 27 flap discs, and Z-LION R-Type diamond roll lock discs—in seconds. This versatility lets you adapt to different tasks, from aggressive cutting to delicate polishing, without missing a beat.

Leveraging quick change mechanisms, such as roll lock or press-fit designs, boosts workflow efficiency. You can seamlessly shift between coarse and fine grits, tailored to your specific material and detail needs. Ultimately, these adaptations reduce operator fatigue and keep your projects on track.

Implementing Safety and Control Features

To effectively implement safety and control features in variable speed die grinders, consider integrating advanced technologies that prioritize user protection and precision. Safety features like RAPIDSTOP™ braking halt rotation swiftly, while kickback brakes shut down the motor during stalls, reducing injury risks. Soft-start functions offer smooth engagement, enhancing control from the get-go. Mechanical clutches, such as Makita’s SJS system, shield internal components from damage due to sudden torque.

Control mechanisms are equally essential. Variable speed control lets you tailor RPM to your task, and electronic speed control maintains consistent operation under load. Paddle switches provide immediate stop capabilities, adding precision to detail work. Additionally, digital tool management systems offer remote monitoring, ensuring safety compliance and ideal tool performance on job sites.

Utilizing LED Lighting for Better Visibility

How can LED lighting transform your workspace into a haven of precision and efficiency? By offering bright, near-daylight illumination, LEDs enhance visibility for intricate work. With LED brightness adjustment, you can tailor the light intensity to your task, reducing eye strain and fatigue during long sessions. Color temperature optimization guarantees natural color rendering, helping you distinguish fine details and color nuances in small parts.

LEDs’ adjustable beam angles focus light directly on your work area, minimizing spillover and eliminating the need for extra lighting tools. Their vibration resistance and long lifespan mean you spend less time on maintenance and more on perfecting your craft. With instant-on illumination, you’re ready to work immediately, keeping your projects moving smoothly and safely.

Customizing Speed Presets for Consistency

While LED lighting enhances your workspace by improving visibility, the art of customizing speed presets on your variable speed die grinder can greatly boost precision and efficiency. Leveraging speed adjustment techniques tailored to specific tasks—like cutting, grinding, or polishing—guarantees you achieve peak results. Using operational consistency strategies, such as setting a specific RPM range for each material type, helps maintain accuracy and reduces errors.

High-tech tools, like the Milwaukee M18 FUEL, offer apps that allow you to customize settings, enhancing precision. For high material removal, choose higher speeds, but switch to lower speeds for detailed work. Experimenting and documenting effective speed presets streamline your workflow, while safety features like rapid braking guarantee secure operations. Tailor your presets for consistent, quality results.

Conclusion

In your quest for precision, remember that customizing your variable speed die grinder setup is key. By selecting the right speed, preferably between 8,000 and 12,000 RPM, you’ll guarantee control and prevent overheating. Embrace brushless motors and ergonomic designs for comfort and efficiency. Choose versatile accessories and incorporate safety features for peak performance. Don’t forget about LED lighting for visibility. Document speed presets to maintain consistency and elevate your detailed work to a professional level.