In this article, you will discover the incredible world of deburring and surface preparation techniques using heavy-duty die grinders. With their powerful motors and versatile attachments, these grinders have become essential tools in various industries. From removing sharp burrs to achieving smooth surfaces, we will explore the different techniques that can be employed to enhance the quality and finish of your workpieces. Whether you are a metalworker, woodworker, or fabricator, this article aims to provide you with valuable insights and practical tips to make your deburring and surface preparation processes more efficient and effective. So, grab your die grinder and get ready to unlock a whole new level of precision and perfection in your craftsmanship.

Understanding Deburring

Introduction to Deburring

Deburring is a process that involves the removal of burrs or sharp edges from a workpiece in order to achieve a smooth and professional finish. Burrs can be formed during the manufacturing process, such as machining, milling, or drilling, and can negatively impact the aesthetics and functionality of the final product. In order to ensure high-quality results, deburring is an essential step in the production process.

Importance of Deburring

Deburring is not only important for improving the appearance of a workpiece, but it also plays a crucial role in enhancing its functionality and performance. Burrs can cause issues such as interference during assembly, increased friction, and reduced precision. By removing burrs, the overall quality of the workpiece is improved, leading to a longer lifespan, better fit, and enhanced safety.

Types of Burrs

There are several types of burrs that can be present on a workpiece. Understanding the different types is important in determining the appropriate deburring technique to be used. Some common types of burrs include:

-

Poisson burrs: These burrs are caused by the bending or stretching of material during the manufacturing process. They typically have a thin and elongated shape.

-

Tear burrs: Tear burrs occur when the material is torn during the machining process. They often have irregular shapes and can be sharp.

-

Breakout burrs: Breakout burrs happen when the material fractures or breaks during drilling or cutting operations. They can vary in size and shape.

-

Chip burrs: Chip burrs are formed when small chips of material are left on the surface of the workpiece after machining. They can be easily removed by deburring techniques.

Common Deburring Techniques

There are various techniques available for deburring, and the choice of technique depends on the type of burr and the material being worked on. Here are some common deburring techniques:

-

Grinding: Grinding is a widely used deburring technique that involves the use of abrasive grinding wheels to remove burrs from the workpiece. It is effective for removing larger burrs and creating a smooth surface finish.

-

Sandpapering: Sandpapering is a manual deburring technique that involves using sandpaper to remove burrs by rubbing them against the workpiece. It is suitable for smaller burrs and can be done by hand or with the help of a sanding block.

-

Wire Brushing: Wire brushing utilizes a wire brush or wire wheel attachment on a die grinder to remove burrs. This technique is effective for both light and heavy burrs and can be used on various materials.

-

Belt Sanding: Belt sanding involves the use of a belt sander, which is equipped with an abrasive belt, to remove burrs. This technique is especially useful for larger and more stubborn burrs.

Introduction to Heavy-duty Die Grinders

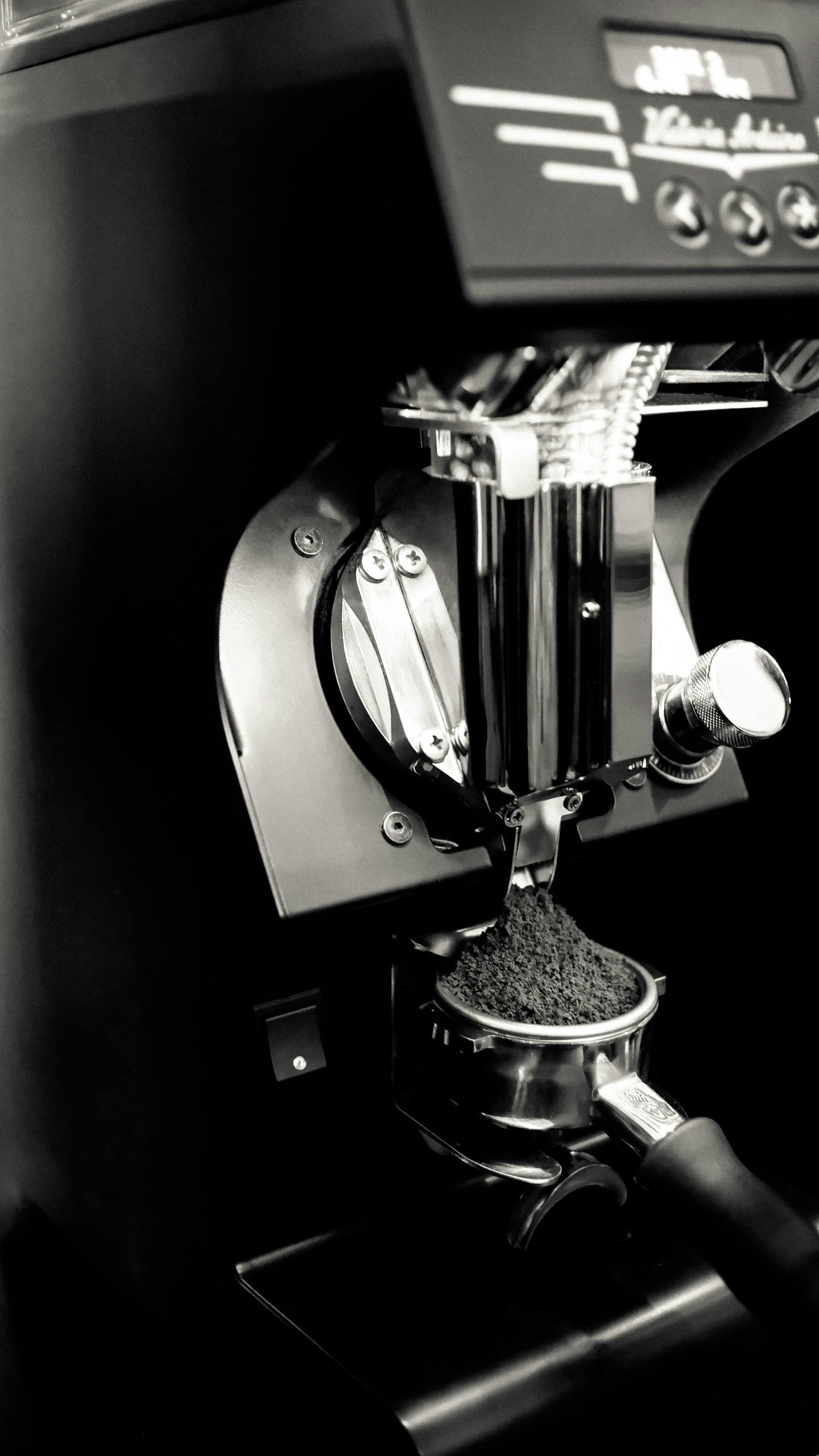

Definition and Function

A heavy-duty die grinder is a powerful and versatile handheld tool that is specifically designed for precision cutting, grinding, and polishing applications. It is commonly used in industrial settings where high-speed rotary action is required to remove material, shape surfaces, and achieve smooth finishes. Heavy-duty die grinders are equipped with powerful motors and durable construction, making them suitable for demanding tasks.

Advantages of Heavy-duty Die Grinders

Heavy-duty die grinders offer several advantages that make them an ideal choice for deburring and surface preparation tasks. Some key advantages include:

-

Power and Efficiency: Heavy-duty die grinders are equipped with high-performance motors that deliver significant power, allowing for efficient material removal and faster completion of tasks.

-

Versatility: These die grinders can be used with a wide range of abrasive attachments, allowing for various deburring and surface preparation techniques. They can handle different materials, including metal, wood, and plastic.

-

Precision and Control: Heavy-duty die grinders offer excellent control and precision, allowing operators to achieve accurate and detailed results. They are particularly suitable for intricate deburring tasks that require precision.

-

Durability: Designed for heavy-duty use, these die grinders are built to withstand the toughest conditions and the rigors of industrial applications. They are made from high-quality materials that ensure long-lasting durability.

Features to Consider When Choosing a Die Grinder

When choosing a heavy-duty die grinder, there are several key features to consider to ensure that you select the right tool for your specific needs. These features include:

-

Power Rating: Consider the power rating of the die grinder, which is typically measured in watts or amps. A higher power rating indicates more power and capability for heavy-duty applications.

-

Speed Control: Look for a die grinder with adjustable speed settings, as different materials and tasks require different speeds. Having control over the speed allows for greater precision and flexibility.

-

Ergonomics: Consider the ergonomics of the tool, including the handle design and weight distribution. Look for a die grinder that is comfortable to hold and operate for extended periods of time.

-

Attachment Compatibility: Ensure that the die grinder is compatible with a variety of attachments, such as grinding wheels, sanding discs, wire brushes, and belt sanders. This ensures versatility and the ability to perform different deburring and surface preparation techniques.

Techniques for Deburring with Heavy-duty Die Grinders

Grinding

Grinding is one of the most commonly used techniques for deburring with heavy-duty die grinders. It involves the use of abrasive grinding wheels that rotate at high speeds to remove burrs and achieve a smooth surface finish. The die grinder is held at a specific angle and moved across the workpiece in a controlled manner, allowing the grinding wheel to make contact with the burr and remove it. The operator can adjust the pressure and speed of the grinder to achieve the desired result.

Sandpapering

Sandpapering is a manual deburring technique that can be performed using a heavy-duty die grinder. It involves attaching a sanding disc or sandpaper sheets to the grinder and rubbing them against the burrs to remove them. Sandpapering is particularly effective for smaller burrs and intricate surfaces that require detailed deburring. The operator needs to hold the die grinder firmly and apply even pressure while sanding to achieve a smooth and consistent finish.

Wire Brushing

Wire brushing is another commonly used technique for deburring with heavy-duty die grinders. It involves attaching a wire brush or wire wheel to the die grinder and using it to remove burrs from the workpiece. Wire brushing is effective for both light and heavy burrs, and it is suitable for various materials, including metal, wood, and plastic. The wire brush spins at high speeds and makes contact with the burrs, quickly removing them and leaving a smooth surface behind.

Belt Sanding

Belt sanding is a technique that utilizes a belt sander, which is equipped with an abrasive belt, to remove burrs from a workpiece. The heavy-duty die grinder is used to hold the workpiece against the moving belt, allowing the abrasive belt to make contact with the burrs and remove them. Belt sanding is particularly useful for larger and more stubborn burrs that require more aggressive removal. The operator needs to ensure proper positioning of the workpiece and apply even pressure to achieve an even and consistent deburring.

Surface Preparation with Heavy-duty Die Grinders

Importance of Surface Preparation

Surface preparation is a critical step in many applications, as it ensures that the surface is clean, smooth, and ready for further processing or finishing. Surface preparation with heavy-duty die grinders is essential for achieving optimal results in tasks such as removing oxidation and rust, coating removal, and smoothing and polishing surfaces. Proper surface preparation ensures better adhesion of coatings, improved aesthetics, and enhanced durability of the final product.

Removing Oxidation and Rust

Heavy-duty die grinders are effective tools for removing oxidation and rust from metal surfaces. The rotary action of the die grinder, combined with abrasive attachments such as grinding wheels or wire brushes, can quickly remove the corroded layer and reveal a clean and smooth surface. The operator needs to be cautious and apply even pressure when removing oxidation and rust to avoid damaging the underlying material.

Coating Removal

Coating removal is another common task that can be efficiently performed using heavy-duty die grinders. Whether it is paint, powder coating, or other types of coatings, die grinders equipped with appropriate abrasive attachments can effectively remove the coatings without damaging the underlying material. The operator needs to select the right abrasive attachment and adjust the speed and pressure to achieve optimal results.

Smoothing and Polishing Surfaces

Heavy-duty die grinders are also useful for smoothing and polishing surfaces to achieve a desired finish. By using abrasive attachments such as sanding discs or polishing pads, the operator can carefully remove imperfections, scratches, and roughness from the surface, resulting in a smooth and polished finish. The choice of abrasive attachment and the technique used depends on the material and the desired level of smoothness and shine.

Safety Precautions for Using Heavy-duty Die Grinders

Protective Gear

When using heavy-duty die grinders, it is essential to wear appropriate personal protective equipment (PPE) to ensure safety. This includes safety glasses or goggles to protect the eyes from flying debris, as well as ear protection to reduce the noise generated by the die grinder. Additionally, wearing gloves can provide extra protection for the hands and reduce the risk of cuts or abrasions.

Proper Tool Handling

Proper tool handling is crucial to prevent accidents and injuries when using heavy-duty die grinders. Always hold the die grinder firmly with both hands while operating, and ensure that the power cord is not in the way or at risk of being damaged. Keep a secure grip on the tool and maintain control over its movement at all times. If the tool starts to vibrate excessively or feel unusual, stop using it immediately and inspect for any issues.

Workpiece Fixation

To prevent the workpiece from moving or shifting during the deburring or surface preparation process, it is important to secure it properly. Use clamps, vices, or other appropriate methods to firmly hold the workpiece in place. This helps to maintain stability and control during operation, reducing the risk of accidents or damage to the workpiece.

Maintenance and Inspection

Regular maintenance and inspection of the heavy-duty die grinder are necessary to ensure its safe and efficient operation. Keep the tool clean and free from dust, debris, or any other obstructions that can affect its performance. Check the power cord for any signs of damage, and inspect the attachments for wear or defects. If any issues are detected, it is important to address them promptly and avoid using the tool until it has been properly repaired or replaced.

Choosing the Right Tooling for Deburring and Surface Preparation

Selecting the Right Abrasives

Choosing the right abrasives is crucial to achieve effective deburring and surface preparation results. Different abrasives are designed for specific tasks and materials, so it is important to consider factors such as grit size, abrasive material, and durability. For example, for heavy burrs and rough surfaces, coarse grit abrasives are more suitable, while fine grit abrasives are better for finishing and polishing. Experimenting with different abrasives and understanding their characteristics can help in selecting the most appropriate ones for specific applications.

Grinding Wheel Selection

When it comes to grinding, selecting the right grinding wheel is essential for optimal deburring results. Factors to consider include the wheel material, wheel thickness, and the grain size or grit. Different materials require different types of grinding wheels, such as aluminum oxide for ferrous metals and silicon carbide for non-ferrous metals. Thicker wheels are generally more durable and can withstand heavy-duty applications, while finer grit wheels provide a smoother surface finish.

Wire Brush Selection

Wire brushes are commonly used for aggressive deburring and surface cleaning tasks. When selecting wire brushes for heavy-duty die grinders, consider factors such as the wire type, wire thickness, and brush diameter. Different wire types, such as stainless steel or brass, are suitable for different materials. Thicker wires are more durable and can handle tougher burrs, while thinner wires provide finer deburring. The brush diameter should match the size of the workpiece and the area that needs to be deburred.

Backing Pad Options

Backing pads are used to securely attach abrasive discs or pads to the heavy-duty die grinder. When choosing backing pads, consider factors such as the pad material, size, and attachment method. The pad material should be compatible with the abrasive discs or pads being used, and it should provide sufficient support and flexibility. The size of the backing pad should match the size of the abrasive disc or pad, and the attachment method should be secure and reliable to prevent dislodgment during operation.

Best Practices for Efficient Deburring and Surface Preparation

Establishing a Methodical Approach

To ensure efficient and consistent deburring and surface preparation, it is important to establish a methodical approach. This involves planning and organizing the tasks, identifying the most appropriate deburring techniques and tooling, and setting a logical sequence for the operations. By having a structured approach, operators can save time, minimize errors, and achieve consistent results.

Maintaining Consistency

Consistency is key when it comes to deburring and surface preparation. To maintain consistent results, it is important to apply consistent pressure, speed, and technique throughout the process. Avoid changing or varying these factors too much, as it can lead to uneven deburring or surface finishes. Regularly monitor and adjust the settings as necessary to ensure consistency and achieve the desired results.

Optimizing Speed and Pressure

Finding the right balance between speed and pressure is crucial for efficient deburring and surface preparation. Adjusting the speed and pressure based on the material, burr size, and desired surface finish can help optimize the performance and effectiveness of the heavy-duty die grinder. Experiment with different settings to find the optimal combination that provides the best results.

Monitoring Tool Performance

Regularly monitoring the performance of the heavy-duty die grinder is important to ensure optimal efficiency and prevent any issues. Keep an eye out for any unusual vibrations, overheating, or changes in performance, as these can indicate potential issues. If any problems are detected, stop using the tool immediately and inspect it for any defects or malfunctions. Regular maintenance and inspection can help identify and resolve issues early on, avoiding costly repairs or accidents.

Applications and Industries

Automotive Industry

The automotive industry heavily relies on heavy-duty die grinders for various deburring and surface preparation tasks. From removing burrs on engine components to smoothing and polishing body panels, die grinders play a crucial role in achieving high-quality results. The versatility and power of heavy-duty die grinders make them ideal for automotive applications.

Aerospace Industry

In the aerospace industry, precision and quality are of utmost importance. Heavy-duty die grinders are widely used for deburring and surface preparation tasks on components such as turbine blades, aircraft fuselages, and engine parts. The ability of die grinders to remove burrs and achieve smooth finishes is essential for ensuring the reliability and safety of aerospace components.

Metal Fabrication

Metal fabrication involves the shaping, cutting, and joining of metal materials to create finished products. Heavy-duty die grinders are indispensable tools in metal fabrication, as they can efficiently remove burrs, smooth welds, and prepare surfaces for painting or coating. Whether it is in a small fabrication shop or a large-scale manufacturing facility, die grinders are essential for achieving high-quality metal products.

Woodworking

While heavy-duty die grinders are commonly associated with metalworking, they also have applications in the woodworking industry. Die grinders can be used to deburr wooden surfaces, smooth rough edges, and prepare wood for finishing. With the appropriate abrasive attachments, die grinders can help woodworkers achieve precise and professional results.

Common Challenges and Troubleshooting Tips

Clogging of Abrasives

One common challenge when using heavy-duty die grinders is the clogging of abrasives, especially when working with materials that produce a lot of dust or debris. To prevent clogging, regularly clean and clear the abrasive attachments during use. Use compressed air or a brush to remove any buildup on the abrasive surface. If clogging continues to be an issue, consider using a coarser grit abrasive or adding a lubricant to reduce friction and heat.

Tool Overheating

Tool overheating can occur during extended use or when working with heavy burrs or hard materials. Overheating can negatively affect the performance and lifespan of the die grinder. To prevent overheating, avoid excessive pressure or prolonged continuous use. Take short breaks during extended operations to allow the tool to cool down. If overheating persists, consider using a die grinder with a higher power rating or periodic cooling breaks to prevent damage.

Vibration and Inaccuracy

Excessive vibration or inaccuracy in the deburring or surface preparation process can lead to uneven results and potential damage to the workpiece. To minimize vibration, ensure that the die grinder is properly balanced and that the attachments are securely fastened. If the die grinder continues to vibrate excessively, inspect the attachments for any signs of damage or wear, and replace if necessary. To improve accuracy, start with lighter pressure and gradually increase as needed, using smooth and controlled motions.

Troubleshooting Guide

Problem: Uneven deburring or surface finish. Solution: Ensure consistent pressure and speed throughout the process. Check for worn or damaged abrasive attachments and replace if necessary. Adjust the pressure or speed to achieve the desired results.

Problem: Excessive noise during operation. Solution: Check for loose or damaged components, such as the guard or backing pad. Tighten or replace as necessary. Ensure that the attachment is securely fastened to the die grinder.

Problem: Tool stalling or decreased performance. Solution: Check for clogged abrasive attachments or debris buildup. Clear as necessary. Inspect the power cord for any damage or loose connections. If the problem persists, stop using the tool and seek professional assistance.

Advancements in Deburring and Surface Preparation Techniques

Robotic Deburring

Advancements in automation technology have led to the development of robotic deburring systems. These systems utilize robots equipped with heavy-duty die grinders to perform consistent and precise deburring tasks. Robotic deburring offers increased efficiency, improved safety, and the ability to handle complex shapes and contours. This technology is particularly beneficial in high-volume production environments.

Non-abrasive Surface Finishing

Another advancement in deburring and surface preparation techniques is the development of non-abrasive surface finishing methods. These methods utilize chemical or electrochemical processes to remove burrs and achieve smooth surfaces without abrasives. Non-abrasive surface finishing is particularly suitable for delicate or heat-sensitive materials, as it minimizes the risk of damage or distortion.

Laser Deburring

Laser deburring is a cutting-edge technique that utilizes laser technology to remove burrs from workpieces. The laser beam is directed at the burrs, causing them to vaporize or melt away. Laser deburring offers exceptional precision and can be used on various materials, including metal, plastic, and ceramics. This technique eliminates the need for physical contact with the workpiece, resulting in reduced tool wear and increased efficiency.

Innovations in Tooling

Advancements in tooling technology have led to the development of innovative attachments and accessories for heavy-duty die grinders. Manufacturers have introduced specialized wheels, brushes, and pads that are designed to provide enhanced performance, durability, and versatility. These innovations allow operators to achieve higher quality results, improve efficiency, and expand the range of applications for heavy-duty die grinders.

In conclusion, understanding deburring and surface preparation techniques using heavy-duty die grinders is essential for achieving high-quality results in various industries. Deburring plays a crucial role in improving the aesthetics, functionality, and performance of workpieces. Heavy-duty die grinders offer the power, versatility, and control necessary for effective deburring and surface preparation. By following safety precautions, selecting the right tooling, and implementing best practices, operators can optimize their deburring and surface preparation processes. With advancements in technology, such as robotic deburring and non-abrasive surface finishing, the field of deburring continues to evolve, providing more efficient and innovative solutions for various industries.