When you explore variable speed die grinder attachments and accessories, you open up a world of possibilities for your projects. With the right tools, you can transform your grinder into a versatile powerhouse. Imagine shaping with precision using carbide burrs, or swiftly removing material with grinding wheels. The right attachment can make all the difference. But how do you choose the best ones for your needs? Let’s explore the options together.

Key Takeaways

- Variable speed die grinders offer enhanced control and versatility across different materials and tasks.

- Carbide burrs are ideal for precision work on hard metals at various speeds.

- Flap discs excel in both grinding and finishing, especially on irregular surfaces.

- Sanding drums provide effective shaping and smoothing for wood, plastics, and metalwork.

- Proper collet size and reducing sleeves ensure secure attachment and reduced vibration.

Types of Die Grinder Attachments

When exploring the world of die grinder attachments, you’ll find a variety of tools designed to enhance your grinding and shaping tasks. Attachment materials like carbide burrs are essential for metalworking, offering precision in shaping, grinding, and deburring hard metals. They’re ideal for professionals needing accuracy and efficiency. In performance comparison, grinding wheels and cutting wheels stand out for heavy-duty material removal and precise cutting in fabrication and repair work. Mounted points and grinding stones, with their varied grit levels, excel in fine shaping and smoothing tasks. Wire brushes and polishing attachments, crafted from materials like steel and brass, are perfect for rust removal and surface preparation. Brands like Milwaukee and Taita Tools are recognized for producing durable die grinder bits, ensuring long-lasting performance in various applications. Each attachment type offers unique benefits, enhancing your die grinder’s versatility.

Choosing the Right Collet Size

When you’re selecting the right collet size for your die grinder, compatibility with your tool and attachments is key. It’s essential to match the collet to the shank size of your accessories, ensuring a secure fit and reducing potential issues like vibration. You might also consider reducing sleeves, which allow for greater flexibility when using different shank sizes with a single collet. Additionally, considering the body material options like composite, aluminum, and steel housings can also influence the overall performance and suitability of your tool for specific applications.

Collet Size Compatibility

Choosing the right collet size for your die grinder is essential for guaranteeing best performance and safety. You’ll find that collet size variations, such as the common 1/4 inch and 1/8 inch, accommodate different attachment shank diameters. For precision work, higher speed pencil grinders often use smaller 1/8 inch collets. On the other hand, 1/4 inch collets, as seen in models like the Jet JAT-404, handle a broader range of attachments. Collet maintenance tips include regularly checking for wear and confirming they’re made from high-quality materials to minimize runout. Proper collet selection prevents slippage and vibration, preserving your tool’s lifespan and enhancing your work’s precision. Remember, the right collet guarantees compatibility and safety across varying applications. Milwaukee Style Die Grinder Collets are made from high-quality U.S. Alloy steel, ensuring durability and precision in your grinding tasks.

Reducing Sleeve Options

A well-chosen reducing sleeve can greatly enhance the versatility of your die grinder by allowing you to use smaller accessories with larger collets. When considering reducing sleeve selection, it’s essential to match the sleeve’s inner diameter with the accessory shank and the outer diameter with the collet size. This guarantees a snug fit, preventing accessory slippage and maintaining tool precision. Die grinders are versatile tools that handle tasks from rust removal to wood carving, making the right reducing sleeve choice crucial for maximizing their functionality.

For sleeve installation, first, verify the sleeve matches your accessory and collet sizes. Insert the sleeve into the collet, then secure the accessory in place. Opt for hardened steel for durability or brass for delicate shafts. Regularly inspect for wear and avoid mixing brands without checking fit. Following these steps guarantees safe, efficient operation and extends the lifespan of your tool.

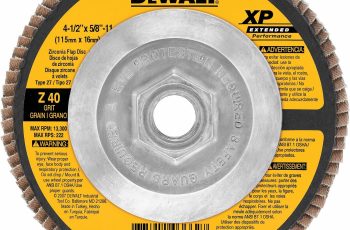

Understanding Abrasive Wheels and Flap Discs

When you’re tackling material removal and surface preparation with a variable speed die grinder, understanding abrasive wheels and flap discs is essential. You’ll want to select the right type based on your project’s requirements, whether it’s for aggressive stock removal or achieving a smooth finish. Consider the compatibility of the abrasive material with the surface you’re working on to guarantee efficient and effective results.

Material Removal Techniques

Immerse yourself in the world of material removal techniques with a focus on abrasive wheels and flap discs, essential in shaping and finishing metal surfaces. Grinding wheels, crafted from abrasives like aluminum oxide and silicon carbide, offer varied grinding efficiency across metals. Choose softer wheels for a gentler cut and harder ones for aggressive material removal. Flap discs, with their overlapping abrasive flaps, balance grinding and finishing, excelling on irregular surfaces by maintaining controlled material removal with less heat.

In die grinder operations, material removal hinges on factors like abrasive grain size, tool and workpiece hardness, and rotational speed. Always maintain consistent motion to prevent overheating. Speed control on variable speed die grinders is vital to optimize abrasive life and achieve the desired finish.

Surface Preparation Essentials

As you investigate surface preparation, understanding abrasive wheels and flap discs is essential for achieving ideal results. Abrasive wheels, with their bonded abrasive grains, are perfect for material removal and surface shaping. They’re heavier and more aggressive, making them ideal for rapid stock removal on flat surfaces. However, their limited flexibility and higher heat generation require careful handling. For more versatile surface preparation techniques, consider flap discs. These consist of overlapping abrasive flaps that offer consistent cutting action and self-renewing efficiency. Their flexibility suits curved surfaces, and they come in various abrasive material selections like ceramic alumina and zirconia alumina. Choosing the right tool based on your project’s needs will guarantee effective and efficient surface preparation.

Compatibility and Selection

To guarantee your variable speed die grinder performs at its best and safely, understanding the compatibility and selection of abrasive wheels and flap discs is essential. First, confirm attachment compatibility by matching the RPM rating of the abrasive wheel to your grinder’s maximum speed. The wheel’s diameter and arbor hole size must align with your tool’s specs. For flap discs, selection criteria include matching the die grinder’s shank size and choosing the right abrasive material for your workpiece. Always verify these components meet or exceed the grinder’s speed to avoid accidents. Additionally, check manufacturer guidelines to maintain warranty and safety. Proper selection keeps your tool effective and durable, confirming every task is done efficiently.

Utilizing Cutting Wheels for Precision Tasks

When it comes to precision tasks, utilizing cutting wheels with a variable speed die grinder offers unparalleled versatility and control. You can master cutting techniques for various precision applications like slotting, trimming, and deburring. These tasks are easily managed by selecting the right wheel, typically up to 2 inches in diameter and 1/32-inch wide, ensuring a snug fit in your grinder’s collet.

Grinding Stones and Carbide Burrs Applications

Grinding stones and carbide burrs are essential attachments for a variable speed die grinder, offering versatility and precision in various applications. With the right grinding techniques, aluminum oxide stones excel on steel, while silicon carbide stones suit non-ferrous metals and stone. They’re perfect for tasks like smoothing welds and intricate stone carving. Carbide burrs, with their diverse burr shapes, are indispensable for deburring, heavy material removal, and intricate detailing on tough metals. Their tungsten carbide construction guarantees longevity, even on stainless steel. The variable speed control of your die grinder allows fine-tuning from 8,000 to 35,000 RPM, guaranteeing peak heat management and application precision. This versatility makes switching between grinding stones and burrs seamless and efficient for any project.

Versatility of Sanding Drums

While grinding stones and carbide burrs handle heavy-duty tasks with finesse, sanding drums offer a different kind of versatility for your variable speed die grinder. Sanding drum applications cover an impressive range, from shaping wood and smoothing plastics to detailing metalwork. Their ability to reach curved and irregular surfaces makes them ideal for automotive and woodworking projects. You’ll appreciate their adaptability with multiple grit selection strategies; starting with coarse grits for material removal, then progressing to finer grits for a polished finish. Swapping out the sanding sleeves is a breeze, allowing you to tailor the surface texture without changing attachments. Whether you’re working in tight spaces or on delicate materials, sanding drums provide precision and efficiency across various tasks.

Safety and Maintenance of Attachments

Before diving into any project with your variable speed die grinder, it’s crucial to prioritize safety and maintenance of the attachments. Start by inspecting all grinding bits, discs, and burrs for damage, ensuring attachment safety. Verify the accessory’s rated RPM matches or exceeds the grinder’s speed to prevent failure. Secure attachments properly, avoiding over-tightening. Always wear ANSI-approved eye protection and suitable gloves to reduce injury risks.

For maintenance practices, regularly inspect and replace worn parts, avoiding moisture exposure. Follow the manufacturer’s procedures for cleaning, lubrication, and pressure release. Monitor for dust buildup at the attachment interface, ensuring a secure fit. Adjust speed according to attachment specs, and never force the tool. Adhere to regulatory guidelines, using proper guards and inspecting cords and hoses.

Conclusion

By exploring variable speed die grinder attachments and accessories, you can enhance your tool’s versatility and efficiency. Whether you’re shaping, cutting, or sanding, there’s an attachment perfect for your project. Always choose the right collet size and understand the materials you’re working with to guarantee the best results. Investing in high-quality accessories not only boosts performance but also extends the life of your tool. Remember, proper safety and maintenance are key to maximizing your grinder’s potential.