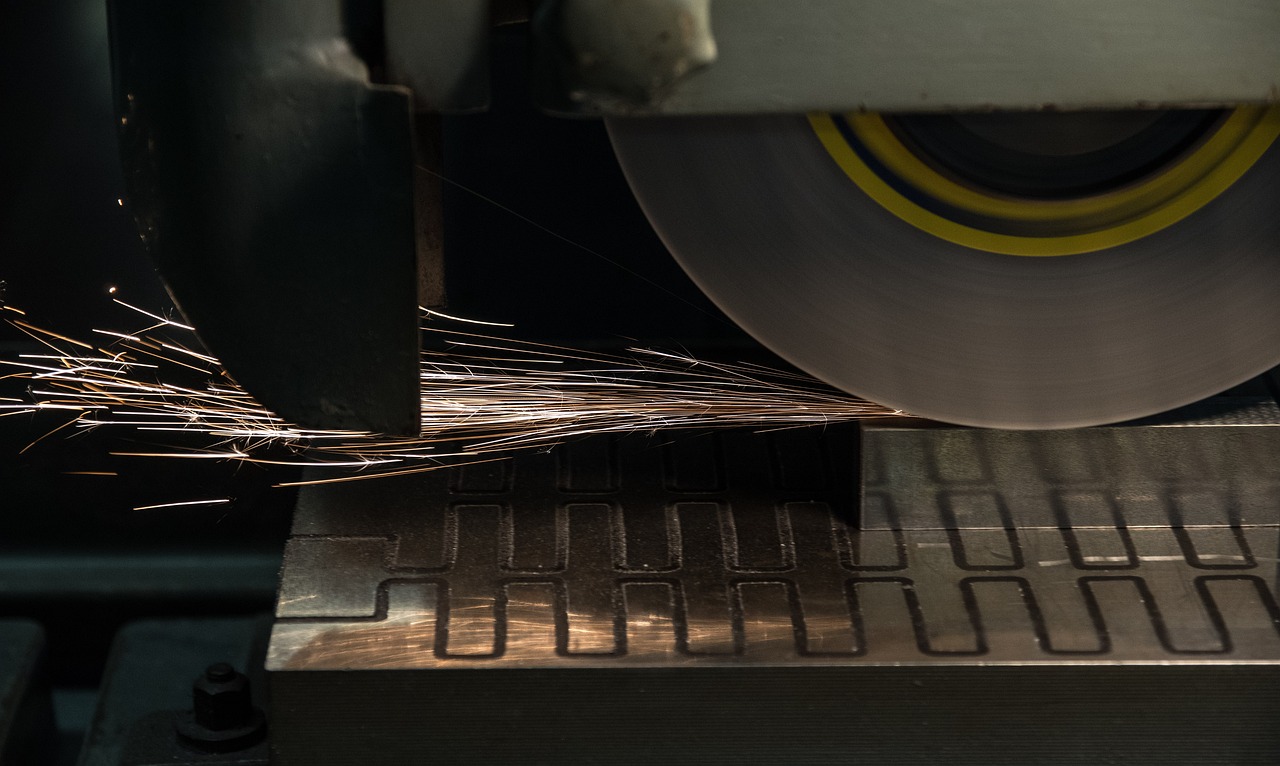

If you’re looking to take your precision work to the next level, then mastering the art of grinding techniques with electric die grinders is a must. These powerful tools have the ability to shape and refine a variety of materials with unparalleled accuracy. Whether you’re a DIY enthusiast or a professional craftsman, this article will guide you through the essential techniques that will help you achieve precise results every time. From selecting the right bit to maintaining proper control, get ready to elevate your grinding game and unlock a world of possibilities in your projects.

Choosing the Right Die Grinder

When it comes to choosing the right die grinder for your needs, there are several factors to consider. One of the first things to think about is the power and speed of the grinder. Different tasks may require different levels of power, so it’s important to choose a die grinder that has enough power to handle the job. Additionally, the speed of the grinder can impact the efficiency and effectiveness of your grinding, so be sure to choose a grinder with a speed that is appropriate for your needs.

Another important consideration when selecting a die grinder is the size and weight of the tool. The size and weight of the grinder can affect how comfortable it is to use and maneuver. If you’re working on a project that requires you to hold the grinder for extended periods of time, you’ll want to choose a grinder that is lightweight and ergonomically designed for comfort.

Selecting the Appropriate Grinding Wheel

Choosing the right grinding wheel is essential for achieving the desired results. One of the first things to consider is the type and material of the grinding wheel. There are various types and materials available, each designed for specific applications. For example, a grinding wheel made of aluminum oxide is suitable for general purpose grinding, while a silicon carbide wheel is better suited for grinding hard materials like stone or glass.

In addition to the type and material, the size of the grinding wheel is also important. The size of the wheel should be compatible with the size of the grinder you are using. Using a wheel that is too large or too small can lead to inefficiency and potentially unsafe grinding conditions.

Grit and hardness are two other important factors to consider when selecting a grinding wheel. The grit size determines the coarseness or fineness of the abrasive particles on the wheel. A higher grit number indicates a finer abrasive, while a lower grit number indicates a coarser abrasive. The hardness of the wheel is also important as it affects the durability and lifespan of the wheel. So, consider the specific requirements of your grinding task and choose a wheel with the appropriate grit and hardness.

Safety Precautions and Personal Protective Equipment

Before you begin grinding with a die grinder, it’s crucial to prioritize safety. One of the first safety measures to take is wearing safety glasses and a face shield. Grinding can produce sparks, debris, and dust, which can be hazardous to your eyes and face. By wearing safety glasses and a face shield, you can protect your eyes and face from potential injuries.

Additionally, it’s important to use ear protection when operating a die grinder. The high-speed rotation of the grinder can create significant noise levels, which can potentially damage your hearing. To safeguard your hearing, consider using earplugs or earmuffs to reduce the noise exposure.

Another essential safety measure is wearing protective gloves and clothing. Grinding generates heat, flying debris, and potential contact with sharp edges. Therefore, it is recommended to wear gloves that are resistant to cuts and abrasions, as well as clothing that covers your arms and legs to protect against flying particles.

Understanding Grinding Techniques

To achieve precise and effective grinding, it’s important to understand and practice proper grinding techniques. One important aspect is applying the right pressure while grinding. Applying too much pressure can cause excessive heat buildup and can potentially damage the workpiece or the grinding wheel. On the other hand, applying too little pressure may result in ineffective grinding. Find the right balance and apply consistent pressure for optimal results.

Along with the right pressure, maintaining a steady hand is crucial. Shaky or unstable grinding can lead to uneven surfaces and compromised accuracy. Practice holding the die grinder with a firm grip and steady hand to ensure smooth and controlled grinding.

Furthermore, using proper grinding angles is key to achieving the desired shape and finish. Experiment with different angles to find the most effective and efficient grinding technique for your specific task. For example, a 45-degree angle may work well for rough grinding, while a more shallow angle may be better for finishing and polishing.

Setting Up the Workpiece

Before you begin grinding, it’s important to properly set up the workpiece. Secure the workpiece using clamps or a vise to ensure it remains in place during the grinding process. A loose or unstable workpiece can lead to poor results and potential accidents. Take the time to properly secure the workpiece before starting.

In addition to securing the workpiece, it’s important to ensure that it is stable. Any movement or vibration of the workpiece during grinding can affect the precision and accuracy of the results. Check that the workpiece is firmly positioned and supported to minimize any unwanted movement.

Finally, lock the die grinder in place to prevent any accidental movement. Many die grinders have a locking mechanism or a spindle lock that can be engaged to keep the grinding tool stable during use. Make use of this feature to ensure a consistent and controlled grinding experience.

Grinding Techniques for Different Materials

Different materials require different grinding techniques to achieve the desired results. When grinding metal, it’s important to use a grinding wheel specifically designed for metal grinding. These wheels typically have a higher hardness and are more resistant to heat buildup. Take care not to apply excessive pressure, as overheating the metal can result in altered properties and potential grinding wheel damage.

When grinding wood, it’s crucial to use a grinding wheel that is intended for wood applications. Wood grinding wheels are typically coarser and have a higher tooth count to effectively remove material without causing excessive heat or damage to the wood. Use a smooth and controlled grinding motion to avoid chipping or splintering the wood.

Similarly, when grinding plastic, it’s important to choose a grinding wheel specifically designed for plastic applications. Grinding wheels for plastic are typically softer and have a higher tooth count to prevent melting or damaging the plastic. Use light pressure and a slow grinding speed to minimize heat buildup and avoid any potential distortion or damage to the plastic.

Avoiding Common Grinding Mistakes

While grinding, it’s important to be aware of and avoid common mistakes that can compromise the quality of your work. One common mistake is overheating the workpiece. Grinding generates heat, and excessive heat can lead to warping, discoloration, or even structural changes in the material being ground. To prevent overheating, be sure to use the appropriate grinding wheel for the material, apply consistent pressure, and take breaks when necessary to allow the workpiece to cool.

Creating uneven surfaces is another common grinding mistake to watch out for. Uneven surfaces can result from uneven grinding pressure or an inconsistent grinding technique. To achieve a smooth and even surface, be mindful of your grinding technique, and ensure that you are applying consistent pressure and maintaining a steady hand.

Applying excessive pressure is another mistake to avoid. While it may seem like more pressure will result in faster grinding, applying excessive pressure can lead to unnecessary heat buildup, excessive wear on the grinding wheel, and potentially damage the workpiece. Find the optimal balance of pressure for the specific material and grinding task at hand.

Performing Regular Maintenance

To keep your die grinder performing at its best, regular maintenance is essential. One important maintenance task is cleaning and lubricating the grinder. Grinding can produce debris and particles that can accumulate and affect the performance of the tool. Clean the grinder regularly, removing any built-up debris and lubricate the moving parts to ensure smooth operation.

Inspecting and replacing grinding wheels is another important maintenance task. Over time, grinding wheels can wear down, become damaged, or lose their effectiveness. Regularly inspect the grinding wheels for any signs of wear or damage, and replace them as needed to maintain optimal grinding performance.

Checking and properly aligning accessories is also crucial for maintaining the functionality of your die grinder. Ensure that any accessories, such as grinding attachments or collets, are properly aligned and secured before use. Misaligned accessories can affect the accuracy of your grinding and potentially cause damage to the grinder or workpiece.

Troubleshooting Common Issues

Despite proper maintenance and use, you may encounter some common issues when using a die grinder. One potential issue is grinder stalling or overheating. If your grinder stalls or becomes excessively hot during use, it may indicate a problem with the power supply or a faulty grinding wheel. Check the power supply and ensure it meets the requirements of the grinder, and inspect the grinding wheel for any signs of wear or damage.

Excessive vibration or noisy operation can also be a cause for concern. Excessive vibration may indicate an unbalanced grinding wheel or a problem with the grinder’s internal components. If you encounter excessive vibration or noise, it’s recommended to stop using the grinder and inspect it for any potential issues. Consult the grinder’s manual or contact the manufacturer for troubleshooting guidance.

Inconsistent grinding results can also be a common issue. If you find that the grinder is not providing consistent results, it may be due to an improper grinding technique, a worn or damaged grinding wheel, or an issue with the grinder itself. Assess your grinding technique, inspect the grinding wheel for wear or damage, and ensure that the grinder is properly maintained and aligned.

Mastering Advanced Grinding Techniques

Once you have mastered the basic grinding techniques, you can begin exploring more advanced techniques for specific applications. Grinding curves and complex shapes requires a high level of control and precision. Take your time and practice on scrap material before attempting complex shapes on your workpiece. Experiment with different grinding angles and motions to achieve the desired curves or intricate designs.

Creating fine surface finishes is another advanced grinding technique. To achieve a smooth and polished surface, use a finer grit grinding wheel and gradually work your way up to achieve the desired finish. Take care to maintain a steady hand and apply consistent pressure for an even and uniform finish.

Working with tight spaces can present its own set of challenges. In these situations, consider using smaller grinding attachments or accessories to access hard-to-reach areas. It may also be helpful to modify the shape or size of the grinding wheel to better fit the confined space. Exercise caution and maintain control in tight spaces to avoid accidental damage or injury.

In conclusion, mastering the art of grinding with an electric die grinder requires careful consideration of various factors, including choosing the right die grinder, selecting the appropriate grinding wheel, following safety precautions, understanding proper grinding techniques, setting up the workpiece correctly, avoiding common mistakes, performing regular maintenance, troubleshooting issues, and exploring advanced grinding techniques. With the right knowledge, practice, and attention to detail, you can achieve precise and efficient grinding results for a wide range of materials and applications.