Enhance your workshop’s efficiency with the Norton Gemini Grinding Wheel, Crystolon Type 01. This medium 60 grit, silicone carbide grinding wheel is perfect for bench grinders, providing excellent shape holding and resistance to wear. Whether you need to deburr or sharpen tools, this versatile wheel fits most arbor sizes and operates at speeds up to 4140 RPM. Ideal for general-purpose applications, it’s designed to tackle carbide tooling and nonferrous materials with ease. Elevate your tool sharpening game with this durable, well-crafted addition to your bench or pedestal grinder setup. Have you been searching for a dependable grinding wheel to enhance your bench grinder’s performance? If so, the Norton Gemini Grinding Wheel might just be the product you’re looking for. In this detailed review, you’ll discover why this specific grinding wheel could be a valuable addition to your workshop.

What is the Norton Gemini Grinding Wheel?

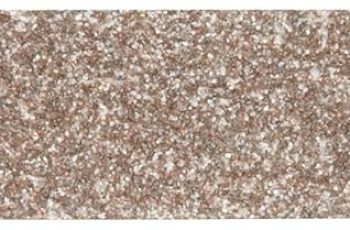

The Norton Gemini Grinding Wheel, Crystolon Type 01 Bench and Pedestal Wheel, Medium 60 Grit, 6 Inch Silicone Carbide Grinding Wheel for Bench Grinder, Pack of 1, is designed for general-purpose grinding applications. This tool is particularly effective when used on carbide tooling and nonferrous materials.

Key Features and Specifications

The Norton Gemini Grinding Wheel comes packed with features that make it a reliable option for a variety of grinding tasks. Here are some of the key features and specifications:

| Feature | Description |

|---|---|

| Material | Silicone carbide |

| Grit | 60 Grit, Medium |

| Dimensions | 6 x 3/4 x 1 Inches |

| Type | Crystolon Type 01 Bench and Pedestal Wheel |

| Speed | Designed to operate at speeds of up to 4140 RPM |

| Suitability | Ideal for deburring, tool sharpening, and general-purpose grinding on carbide and nonferrous materials |

| Packaging | Comes in a pack of 1 grinding wheel |

| Bond | Vitrified bond for wear resistance and superb shape holding |

Material and Build Quality

The material used in the Norton Gemini Grinding Wheel is silicone carbide. This material is known for its durability and efficiency, particularly when it comes to grinding carbide tooling and nonferrous materials. The vitrified bond ensures that the wheel maintains its shape and resists wear, which adds to its long lifespan.

Setting Up Your Norton Gemini Grinding Wheel

Getting started with the Norton Gemini Grinding Wheel is straightforward. The wheel is designed with telescoping bushings to fit most arbor hole sizes, making it versatile and easy to install on various bench grinders.

Installation Process

You’ll find that installing the Norton Gemini Grinding Wheel is not a complicated task. Here’s a step-by-step guide:

- Remove Old Wheel: Start by unplugging your bench grinder. Remove any old grinding wheels by loosening the nuts that secure them in place.

- Inspect Arbor: Check the arbor hole size of your grinder to ensure it matches the telescoping bushings provided with the Norton Gemini Grinding Wheel.

- Fit New Wheel: Insert the wheel onto the arbor, utilizing the telescoping bushings if needed, to ensure a secure fit.

- Tighten Nuts: Secure the wheel in place by tightening the nuts. Make sure it’s firmly attached but avoid over-tightening.

- Test Run: Plug the grinder back in and run it at low speed to ensure that the wheel is correctly installed and runs smoothly without any wobbling.

Safety Measures

Safety should always be a priority when installing and using a grinding wheel. Always wear appropriate protective gear, such as safety glasses and gloves. Make sure the grinder is unplugged during the installation process to avoid accidental startups.

Performance and Efficiency

The primary test of any grinding wheel lies in its performance. Let’s delve into how the Norton Gemini Grinding Wheel fares when put to the test.

Grinding Efficiency

Equipped with medium 60 grit, the Norton Gemini is ideal for various grinding tasks, from deburring to tool sharpening. The silicone carbide material effectively grinds down carbide tooling and nonferrous materials, delivering consistent results.

Shape Holding and Wear Resistance

One of the most notable features of this grinding wheel is its vitrified bond. This bond provides excellent shape holding capability, meaning the wheel retains its form even after multiple uses. It also offers superior resistance to wear, ensuring that the wheel remains effective for a long time.

User Experience

Customer reviews and user experiences offer valuable insights into any product. Here’s how users generally feel about the Norton Gemini Grinding Wheel.

Satisfaction Levels

Most users report high levels of satisfaction, praising the grinding wheel’s durability and efficiency. The ability to maintain its shape and resist wear over time seems to be a standout feature. Users find it versatile and suitable for a variety of tasks, making it a go-to option for both casual and professional users.

Pros and Cons

To give you a more balanced view, let’s summarize the pros and cons based on customer feedback.

Pros:

- High durability thanks to its silicone carbide material

- Efficient performance for both deburring and tool sharpening

- Fits most arbor hole sizes due to its telescoping bushings

- Shape retention and wear resistance owing to the vitrified bond

- Suitable for both bench and pedestal grinders

Cons:

- Comes as a pack of only one grinding wheel

- Medium 60 grit may not be ideal for all types of grinding needs

Applications and Best Use Cases

Understanding the different scenarios where the Norton Gemini Grinding Wheel excels can help you make an informed decision.

Ideal Applications

This grinding wheel is designed for general-purpose grinding applications. Here’s a breakdown of some of its ideal use cases:

- Deburring: Perfect for removing burrs from metalworks, ensuring clean, burr-free edges.

- Tool Sharpening: From chisels to drill bits, this wheel can sharpen various tools, making them ready for use again.

- Carbide Tooling: Especially effective on carbide tooling, delivering efficient grinding results.

- Nonferrous Materials: Works well on nonferrous metals like aluminum and brass, offering versatility in your grinding tasks.

Comparisons to Other Grinding Wheels

To better understand the strengths and weaknesses of the Norton Gemini Grinding Wheel, it is useful to compare it with other options on the market.

Versus Aluminum Oxide Grinding Wheels

Durability:

- The silicone carbide material in the Norton Gemini Grinding Wheel is generally less durable than aluminum oxide but offers superior sharpness for carbide tooling and nonferrous materials.

Applications:

- While aluminum oxide wheels are excellent for grinding steel and ferrous metals, the Norton Gemini shines in applications involving carbide and nonferrous metals.

Versus Diamond Grinding Wheels

Cost:

- Diamond wheels tend to be more expensive than silicone carbide wheels like the Norton Gemini.

Efficiency:

- Diamond wheels are highly effective for precision grinding and harder materials. However, the Norton Gemini offers a more economical solution for general-purpose tasks.

Tips for Maximizing the Norton Gemini Grinding Wheel’s Lifespan

To get the most out of your Norton Gemini Grinding Wheel, consider following these maintenance tips and practices.

Regular Inspection and Cleaning

Make it a habit to inspect your grinding wheel before each use. Look for any signs of wear or damage. Regularly cleaning the wheel helps maintain its efficiency.

Proper Storage

Store the grinding wheel in a dry, cool place away from any heat sources to prevent it from degrading prematurely. Keeping it in its original packaging can also help protect it from dust and moisture.

Optimal Usage

Avoid applying excessive pressure while using the wheel. Let the wheel do the work instead of forcing it, which can lead to premature wear and potential damage.

Frequently Asked Questions

To wrap up, let’s address some common questions about the Norton Gemini Grinding Wheel.

Is the Norton Gemini Grinding Wheel suitable for beginners?

Absolutely! Its user-friendly design and ease of installation make it an excellent choice for beginners. The medium 60 grit is versatile enough to handle a variety of tasks without being too aggressive.

Can the wheel be used for sharpening kitchen knives?

While the Norton Gemini Grinding Wheel excels in tool sharpening, you might want to use a finer grit for kitchen knives to achieve a sharper edge. This wheel is better suited for sharpening chisels, drill bits, and other workshop tools.

Is it compatible with all bench grinders?

Thanks to the telescoping bushings, the Norton Gemini Grinding Wheel is designed to fit most arbor hole sizes, making it compatible with a wide range of bench grinders.

How often should I replace the wheel?

The frequency of replacement depends on the amount of use and the types of materials you’re working with. Regular inspection and maintenance will help you gauge when it’s time for a replacement.

Where can I purchase the Norton Gemini Grinding Wheel?

You can find the Norton Gemini Grinding Wheel at most hardware stores and online marketplaces like Amazon. Ensure you are purchasing from a reputable seller to avoid counterfeit products.

By now, you should have a comprehensive understanding of the Norton Gemini Grinding Wheel’s features, benefits, and applications. Whether you’re a beginner or a seasoned professional, this grinding wheel is designed to deliver consistent, reliable performance for a variety of grinding tasks. So why wait? Enhance your workshop with the Norton Gemini Grinding Wheel today!

Disclosure: As an Amazon Associate, I earn from qualifying purchases.