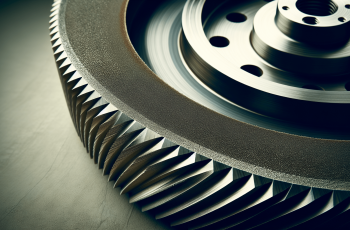

Are you on the hunt for the perfect grinding wheel to suit your heavy-duty needs? Look no further than the Type 01 Straight Gemini Bench & Pedestal Grinding Wheels – straight wheels straightwheels 10 x 1 x 1-1/4. This incredible product is designed to deliver outstanding performance, ensuring that your grinding tasks are smooth, efficient, and precise.

Key Features of Type 01 Straight Gemini Grinding Wheels

One of the main attractions of the Type 01 Straight Gemini Grinding Wheels is their comprehensive set of features that cater to various needs. Let’s break it down:

Versatile Grinding

Whether you’re dealing with hard metals or softer materials, these grinding wheels are versatile enough to handle a variety of tasks. They provide a consistent finish, saving you time and effort.

Durable Build

Crafted to last long, these grinding wheels have a robust construction. They can withstand hard impacts and resist wear-and-tear, making them an excellent investment.

Standard Dimensions

With dimensions of 10 x 1 x 1-1/4, these wheels fit standard bench and pedestal grinders. This ensures broad compatibility, making it easier for you to integrate them into your existing setup.

| Feature | Description |

|---|---|

| Versatile Grinding | Handles various materials with consistent finish |

| Durable Build | Robust construction for long-lasting use |

| Standard Dimensions | Fits most bench and pedestal grinders with 10 x 1 x 1-1/4 size |

Benefits of Using Type 01 Straight Gemini Grinding Wheels

Precision and Efficiency

The key to any successful grinding operation is precision and efficiency. With the Type 01 Straight Gemini Grinding Wheels, you can achieve both without compromising on quality. They are designed to offer smooth operation, reducing the risk of errors.

Easy Installation

No need to waste time fumbling with complicated setups. These wheels are easy to install, enabling you to get started with your grinding tasks swiftly.

Cost-Effective

Given their durability and performance, these grinding wheels are a cost-effective solution for both small-scale and industrial applications. They reduce the frequency of replacements and maintain optimal performance over time.

Increased Productivity

With their efficient grinding capabilities, you can expect a substantial boost in productivity. Whether it’s metalworking or another task, these wheels help you achieve more in less time.

| Benefit | Explanation |

|---|---|

| Precision and Efficiency | Smooth operation minimizes errors |

| Easy Installation | Simple setup allows quick start |

| Cost-Effective | Durable wheels require fewer replacements |

| Increased Productivity | Enhanced grinding capabilities boost task completion speed |

Installation Guidance

Proper installation ensures that you get the best from your grinding wheel. Here are some tips:

Step 1: Safety First

Ensure that you switch off your grinder and unplug it. Wear safety gear like gloves and a face shield to protect against any mishaps.

Step 2: Remove the Old Wheel

Using a wrench, loosen the nut securing the old grinding wheel and carefully remove it.

Step 3: Inspect the Grinder

Before you place the new wheel, inspect the grinder spindle and flanges for any signs of damage or wear.

Step 4: Mount the New Wheel

Place the Type 01 Straight Gemini Grinding Wheel onto the spindle and secure it with the nut. Ensure it is tightly fastened but not overly so, as this can cause damage.

Step 5: Test Run

Plug the grinder back in and do a test run for a few seconds. If everything is stable, you’re good to go.

Important Tip

Always read the manufacturer’s instructions and follow any specific guidelines provided.

Common Misconceptions

Misconception 1: All Grinding Wheels are the Same

Not all grinding wheels offer the same level of performance and durability. The Type 01 Straight Gemini Grinding Wheels stand out due to their specialized features and robust construction.

Misconception 2: Complex Installation

Many people believe that installing a new grinding wheel is a complex task. In reality, with proper guidelines, you can easily install these wheels without much hassle.

Misconception 3: Frequent Replacements Needed

Given their durable build, these grinding wheels don’t require frequent replacements, making them more cost-effective in the long run.

Misconception 4: Limited Application

These wheels are versatile and can handle a wide range of materials, contrary to the belief that grinding wheels have limited applications.

Who Should Use This Product

Industrial Users

If you’re involved in heavy industrial operations, these grinding wheels can handle the stress and deliver reliable performance.

DIY Enthusiasts

For those who love taking on DIY projects, these wheels offer the perfect blend of professional-level performance and ease of use.

Small Workshop Owners

Small-scale operations can benefit from the cost-effectiveness and durability of these grinding wheels, ensuring that you get the most out of your investment.

Maintenance Tips

To ensure that your grinding wheels last long and perform optimally, regular maintenance is essential. Here are some tips:

Regular Cleaning

Keep your wheels clean by removing any built-up debris. This will ensure that they function correctly and reduce wear.

Check for Damage

Regularly inspect the wheels for any signs of cracks or other damage. If you notice any issues, replace the wheel immediately to avoid accidents.

Proper Storage

Store your wheels in a dry place to prevent any damage caused by moisture.

Balance Your Wheel

If you notice vibrations while using the wheel, it may be unbalanced. Ensure that it is correctly mounted and balanced to maintain smooth operation.

| Maintenance Tip | Explanation |

|---|---|

| Regular Cleaning | Remove built-up debris to ensure proper function |

| Check for Damage | Inspect for cracks and replace if necessary |

| Proper Storage | Store in a dry place to prevent moisture damage |

| Balance Your Wheel | Ensure correct mounting to reduce vibrations |

Customer Reviews

High Praise from Professionals

Many professionals in the industry have expressed their satisfaction with the performance and durability of these grinding wheels. The consistency in finish and ease of installation are among the top reasons for their high ratings.

DIY Community Favorite

The DIY community has also shown tremendous love for the Type 01 Straight Gemini Grinding Wheels. Users appreciate how these wheels make complex tasks more manageable.

Reliable for Long-Term Use

Several long-term users have vouched for the reliability of these grinding wheels. Their strong build and consistent performance make them a go-to choice for recurring projects.

Conclusion

The Type 01 Straight Gemini Bench & Pedestal Grinding Wheels – straight wheels straightwheels 10 x 1 x 1-1/4 offer an exceptional blend of durability, efficiency, and versatility. Whether you’re a professional, a DIY enthusiast, or a small workshop owner, these grinding wheels can significantly enhance your productivity while ensuring precision and consistency. With easy installation and minimal maintenance, they stand out as a cost-effective, reliable solution for your grinding needs.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.