In this article, you will discover the exciting world of upgrading and modifying bench grinders. Whether you are a hobbyist or a professional, finding ways to enhance the performance and versatility of your bench grinder can greatly impact your work. From adding better quality wheels and adjustable tool rests to installing a variable speed controller, this article will provide you with valuable tips and insights to take your grinding experience to the next level. So, grab your tools and get ready to unleash the full potential of your bench grinder!

Upgrading Bench Grinders

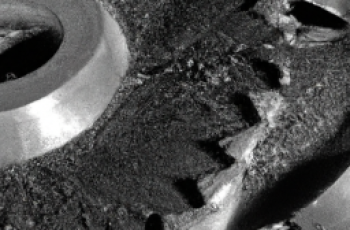

Replacing the Grinding Wheels

One of the first upgrades you can consider for your bench grinder is replacing the grinding wheels. Over time, the original wheels can become worn or damaged, affecting the performance and quality of your grinding tasks. By investing in high-quality replacement wheels, you can ensure smoother and more efficient grinding operations. When selecting new wheels, consider factors such as grit size, material compatibility, and wheel diameter to match your specific needs.

Upgrading the Motor

If you find that your current bench grinder lacks power or struggles to maintain consistent speed, upgrading the motor can greatly improve its performance. A more powerful motor will allow you to tackle tougher grinding tasks and provide better overall results. Additionally, look for a motor that offers variable speed control, enabling you to adjust the grinding speed to match the specific material or task at hand.

Enhancing Safety Features

Safety should always be a top priority when working with any power tool, including bench grinders. Enhancing the safety features of your grinder is essential to protect yourself and minimize the risk of accidents. Consider upgrading to grinder models that feature adjustable eye shields for better visibility and protection against sparks. Adding a sturdy and adjustable tool rest can also improve stability and reduce the likelihood of accidental slips or movements during grinding.

Adding Variable Speed Control

While some bench grinders come with fixed speed settings, adding variable speed control to your grinder can offer greater versatility and control in your grinding operations. Depending on the material or task you’re working on, having the ability to adjust the grinding speed can make a significant difference in achieving optimal results. Look for a speed control module that is compatible with your grinder model and allows you to adjust the speed according to your needs.

Improving Dust Collection

Grinding operations can generate a significant amount of dust and debris, which can not only create a messy work area but also pose health hazards. Upgrading the dust collection system of your bench grinder can help keep your work area cleaner and healthier. Consider adding a dust collection hood or attachment to your grinder and connect it to a shop vacuum or dust collection system. This will effectively capture the majority of the dust and particles generated during grinding, ensuring a cleaner and safer workspace.

Installing a Work Light

Adequate lighting is crucial when working with precision and accuracy on your bench grinder. Installing a work light near your grinder can greatly improve visibility and reduce the chances of mistakes or errors. Opt for a high-quality LED work light that provides bright, focused illumination directly on the grinding area. With improved visibility, you can achieve more precise and consistent results while ensuring your safety.

Upgrading the Tool Rests

Tool rests are essential components of a bench grinder, providing support and stability for your workpieces. However, the standard tool rests that come with most bench grinders may not always offer the desired level of functionality or accuracy. Consider upgrading to customizable tool rests that allow you to adjust the angle and position of your workpiece for optimal grinding. Look for tool rests made from durable materials that can withstand the rigors of grinding tasks.

Adding a Spark Arrestor

Sparks are a common byproduct of grinding operations and can potentially cause fires or injuries if not properly controlled. Adding a spark arrestor to your bench grinder can help minimize the risk of sparks reaching flammable materials or causing accidental ignition. A spark arrestor is typically a metal screen that sits over the grinding wheel, trapping sparks and preventing them from scattering. Ensure the spark arrestor is securely installed and regularly clean it to maintain its effectiveness.

Upgrading the Power Cord

The power cord of your bench grinder plays a crucial role in providing a reliable and safe electrical connection. However, over time, the original power cord may become frayed, damaged, or too short for your needs. Upgrading to a high-quality power cord that is the appropriate length and thickness can ensure a secure and efficient power supply to your grinder. Additionally, consider a cord with added features such as strain relief or a tangle-free design for improved durability and ease of use.

Upgrading the On/Off Switch

The on/off switch of your bench grinder is the primary means of controlling its operation. If your grinder’s switch is unreliable, difficult to reach, or lacks important safety features, upgrading it can greatly enhance the functionality and ease of use. Look for a switch that is conveniently located, responsive, and equipped with safety mechanisms such as a lockout feature to prevent accidental activations. Installing a high-quality on/off switch will provide you with better control over your grinder and contribute to a safer working environment.

Modifying Bench Grinders

Building Custom Tool Rests

If the standard tool rests available for your bench grinder do not meet your specific needs, consider building custom tool rests. Custom tool rests allow you to create a setup that perfectly accommodates the size, shape, and angle requirements of your workpieces. Using sturdy materials such as steel or aluminum, design and build tool rests that offer maximum stability and adjustability. Ensure that the custom tool rests securely attach to your bench grinder, providing a reliable and steady platform for your grinding operations.

Adding a Sharpening Jig

A sharpening jig is a valuable addition to your bench grinder, especially if you frequently sharpen blades or tools. This modification allows for precise and consistent sharpening angles, resulting in enhanced cutting performance and longevity of your tools. There are various types of sharpening jigs available, including adjustable and dedicated jigs for specific tool types. Choose a sharpening jig that suits your needs and is compatible with your bench grinder for efficient and accurate sharpening.

Modifying the Grinding Wheel Guards

The grinding wheel guards that come standard with bench grinders may not always provide the necessary protection or accessibility. Modifying the guards can improve safety and facilitate easier grinding operations. Consider removing or modifying the guards to allow for better visibility and access to the grinding wheel. However, it is crucial to ensure that the modified guards still provide sufficient protection against sparks and debris. Consult the manufacturer’s guidelines or seek professional advice to ensure the modified guards comply with safety standards.

Installing a Water Cooling System

Grinding tasks that generate significant heat can benefit from the installation of a water cooling system on your bench grinder. This modification uses a constant stream of water to effectively cool the grinding wheel and workpiece, preventing overheating and potential damage. A water cooling system typically consists of a reservoir, tubing, and a nozzle that directs the water flow to the appropriate areas. Ensure that the system is securely mounted and properly connected to your bench grinder for efficient and effective cooling during prolonged grinding sessions.

Adding a Wire Wheel

To expand the versatility of your bench grinder and tackle additional tasks, consider adding a wire wheel attachment. A wire wheel can be used for tasks such as removing paint, rust, or corrosion, as well as for light deburring or polishing. Choose a wire wheel that matches the size and arbor of your bench grinder and make sure it is securely mounted. When using the wire wheel, be mindful of the direction of rotation and wear appropriate safety gear, including goggles and gloves, to protect yourself from flying debris.

Modifying the Base for Stability

Stability is crucial when operating a bench grinder to ensure accurate and safe grinding. Modifying the base of your grinder can greatly enhance stability, especially if you frequently work on larger or heavier materials. Consider adding weight to the base or anchoring it to a sturdy workbench to minimize vibrations and prevent the grinder from moving during use. Additionally, you can add rubber feet or pads to the base to provide better grip and reduce the likelihood of slipping or sliding.

Customizing the Bench Grinder Stand

If you frequently use your bench grinder and require a dedicated and ergonomic workspace, customizing the bench grinder stand can greatly improve your comfort and efficiency. Modify the stand to a height and layout that suits your specific needs, ensuring proper alignment between the grinder and your work area. Use durable materials such as steel or wood to construct a sturdy and stable stand. Consider adding storage compartments or shelves to keep your grinding accessories organized and within easy reach.

Modifying the Bench Grinder for Sharpening Lawn Mower Blades

Sharpening lawn mower blades is a common task that can be made more efficient by modifying your bench grinder. To ensure the proper angle and geometry of the blade edge, consider creating a dedicated jig or fixture that securely holds the blade during sharpening. Additionally, you may want to add a blade balancing feature to your modified grinder to ensure a properly balanced blade for optimal cutting performance. Follow the manufacturer’s guidelines and safety precautions when modifying your bench grinder for this specific task.

Converting the Bench Grinder into a Belt Sander

Expanding the functionality of your bench grinder by converting it into a belt sander can save you the expense of purchasing a separate tool. This modification allows you to use your bench grinder for tasks such as shaping, sanding, and finishing larger workpieces. To convert the grinder, you will need to remove the grinding wheels and attach a belt sander attachment that matches the size and specifications of your grinder. Ensure that the attachment is securely mounted and aligned properly for safe and effective operation.

Modifying the Bench Grinder for Polishing Operations

To enhance the versatility of your bench grinder and enable polishing operations, you can modify it to accommodate polishing wheels or buffs. This modification allows you to achieve a high-quality mirror-like finish on metal or other workpieces. Remove the grinding wheels and attach polishing wheels or buffs that are specifically designed for the task. Ensure that the wheels or buffs are securely mounted and that you use the appropriate polishing compounds and techniques for the desired results. Always wear appropriate safety gear, including eye protection and dust masks, when conducting polishing operations.

In conclusion, upgrading and modifying your bench grinder can significantly enhance its performance, versatility, and safety. Whether you choose to replace components, install accessories, or customize the grinder according to your specific needs, these modifications can enhance your grinding operations and make your workspace more efficient and enjoyable. Remember to always prioritize safety and follow the manufacturer’s guidelines and recommendations when upgrading or modifying your bench grinder. With the right modifications, your bench grinder can become a valuable tool that meets all your grinding and other related needs.