Looking for a way to minimize the noise coming from your bench grinder? Look no further! In this article, we will explore some effective strategies to reduce the noise generated by your bench grinder. Whether you use your bench grinder for woodworking projects or metalworking tasks, the constant buzzing and grinding sound can be quite bothersome. By implementing these noise reduction techniques, you can enjoy a quieter and more pleasant working environment. So, let’s get started and discover how you can silence the noise of your bench grinder!

Understanding the Importance of Bench Grinder Noise Reduction

The Effects of Noise Exposure on Health and Well-being

When it comes to using a bench grinder, noise reduction should be a top priority. Excessive noise exposure can have serious implications for your health and well-being. Prolonged exposure to high levels of noise can lead to hearing loss, tinnitus, and other auditory disorders. It can also cause stress, sleep disturbances, and even cardiovascular problems. By reducing the noise generated by your bench grinder, you can protect yourself from these potential health risks and maintain your overall well-being.

The Impact of Noise Pollution on Work Efficiency

Not only does excessive noise pose a threat to your health, but it can also significantly impact your work efficiency. Constant exposure to loud noise can make it difficult to concentrate, communicate effectively, and perform tasks accurately. This can lead to decreased productivity and increased errors in your work. By taking steps to reduce bench grinder noise, you can create a quieter and more conducive work environment, allowing you to work more efficiently and effectively.

Legal Regulations and Standards for Noise in the Workplace

It’s important to note that there are legal regulations and standards in place to protect workers from excessive noise in the workplace. These regulations vary depending on the country and industry, but they generally establish permissible noise exposure limits and require employers to implement noise control measures. By complying with these regulations and standards, employers can ensure the well-being and safety of their employees. Therefore, understanding and adhering to these regulations is crucial when it comes to bench grinder noise reduction.

Identifying the Causes of Bench Grinder Noise

Motor and Gearbox Vibration

One of the primary causes of bench grinder noise is motor and gearbox vibration. When the motor and gearbox are not properly aligned or maintained, they can produce excessive vibration, resulting in a loud and unpleasant noise. To address this issue, regular maintenance and lubrication are essential. By keeping the motor and gearbox properly lubricated and aligned, you can minimize vibration and reduce the noise generated by your bench grinder.

Poorly Maintained or Worn-out Grinding Wheels

Another common cause of bench grinder noise is poorly maintained or worn-out grinding wheels. Over time, grinding wheels can become uneven or worn, leading to increased noise levels. To prevent this, it is important to regularly inspect and maintain your grinding wheels. This includes checking for any signs of wear or damage and replacing them if necessary. By using well-maintained grinding wheels, you can reduce the noise produced by your bench grinder.

Lack of Adequate Noise Insulation

In some cases, the noise produced by a bench grinder can be attributed to the lack of adequate noise insulation. Without proper insulation, the noise generated by the motor, gears, and grinding wheels can easily transmit and amplify, leading to a louder and more disruptive noise. To address this issue, it is recommended to install soundproof enclosures and barriers around the bench grinder. These enclosures and barriers help contain the noise and prevent it from spreading to the surrounding area, creating a quieter work environment.

Steps for Effective Bench Grinder Noise Reduction

Regular Maintenance and Lubrication

Regular maintenance and lubrication are crucial for reducing bench grinder noise. By keeping the motor and gearbox properly lubricated, you can minimize vibration and noise. Additionally, routine maintenance tasks such as tightening belts and pulleys, inspecting wiring connections, and cleaning the grinder can further contribute to noise reduction. Implementing a maintenance schedule and adhering to it will ensure that your bench grinder operates at its optimal performance and produces minimal noise.

Correct Adjustment of Belts and Pulleys

Another essential step in bench grinder noise reduction is the correct adjustment of belts and pulleys. Misaligned or loose belts and pulleys can cause excessive noise and vibration. To rectify this, ensure that the belts are properly tensioned and aligned with the pulleys. Regularly inspect these components and make any necessary adjustments to promote smoother and quieter operation of the bench grinder.

Rebalancing Grinding Wheels

To reduce noise caused by poorly maintained or worn-out grinding wheels, it is important to rebalance them regularly. Imbalanced grinding wheels can create uneven movement and lead to increased noise levels. Balancing the wheels involves adding or removing weight to ensure that they rotate smoothly and silently. By rebalancing your grinding wheels, you can minimize noise and create a more pleasant working environment.

Upgrading to Quieter Motors or Gearboxes

If your bench grinder consistently produces high levels of noise despite regular maintenance and adjustments, it may be worth considering upgrading to quieter motors or gearboxes. Modern advancements in motor and gearbox design have led to the development of quieter and more efficient models. By investing in these upgrades, you can significantly reduce the noise generated by your bench grinder and enhance your overall work experience.

Installing Proper Noise Insulation Measures

Soundproof Enclosures and Barriers

To effectively reduce bench grinder noise, it is recommended to install soundproof enclosures and barriers around the machine. These enclosures are specifically designed to absorb and dampen noise, preventing it from spreading to the surrounding area. Soundproof barriers can also be used to block noise transmission through walls or partitions. By implementing these measures, you can create a quieter and more comfortable work environment, promoting productivity and well-being.

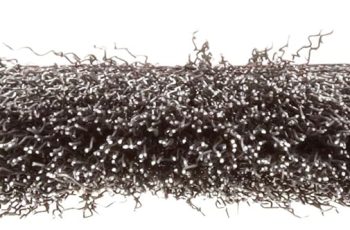

Acoustic Foam and Insulation Mats

In addition to soundproof enclosures, acoustic foam and insulation mats can be used to further reduce bench grinder noise. These materials are designed to absorb sound waves and reduce their reflection, effectively minimizing noise. Acoustic foam can be attached to walls or surfaces surrounding the bench grinder, while insulation mats can be placed under or around the machine. By incorporating these materials, you can significantly decrease noise levels and create a more peaceful workspace.

Vibration-dampening Mounts and Pads

To address the issue of motor and gearbox vibration, vibration-dampening mounts and pads can be installed. These mounts and pads are made from materials designed to absorb and dissipate vibration, effectively reducing the noise produced by the bench grinder. By isolating the machine from its surroundings, these vibration-dampening measures help create a quieter and more stable working environment.

Using Hearing Protection Devices

Types of Hearing Protection Devices

While implementing bench grinder noise reduction measures is essential, it is also important to use appropriate hearing protection devices to further safeguard your hearing. There are various types of hearing protection devices available, including earplugs and earmuffs. Earplugs are small devices that are inserted into the ear canal, while earmuffs are worn over the ears. Both types of devices work by reducing the sound level reaching the ears, providing an additional layer of protection against excessive noise.

Appropriate Selection and Fit

When choosing and using hearing protection devices, it is crucial to select the appropriate type and ensure a proper fit. Different devices offer varying levels of noise reduction, so it’s important to choose the ones that offer sufficient protection for the noise levels in your work environment. Additionally, achieving a proper fit is essential for maximum effectiveness. Earplugs should be inserted correctly and securely, while earmuffs should create a tight seal around the ears. This ensures that the devices provide the intended noise reduction and protection.

Proper Training and Education

Using hearing protection devices effectively requires proper training and education. Employees should be educated on the importance of hearing protection and provided with training on how to correctly use and maintain their hearing protection devices. This includes instructions on fitting, cleaning, and replacing the devices as needed. By promoting proper training and education, employers can empower their workers to take responsibility for their own hearing health and safety.

Implementing Safe Operating Practices

Reducing Grinding Speeds

One effective way to reduce bench grinder noise is by reducing the grinding speeds. Operating the bench grinder at a lower speed can help minimize noise levels without compromising the performance or quality of the grinding process. However, it is important to ensure that the reduced speed still allows for effective and efficient grinding. Finding the right balance will not only help in noise reduction but also contribute to safer and more controlled operation of the bench grinder.

Avoiding Overloading the Grinder

Overloading the bench grinder can lead to increased noise levels and potentially cause damage to the machine. It is important to follow the manufacturer’s recommendations for maximum load capacity and avoid exceeding these limits. By using the bench grinder within its intended capacity, you can prevent excessive strain on the motor and gearbox, resulting in quieter and more reliable operation.

Maintaining Stable Workpiece Support

Another important aspect of safe operating practices is maintaining stable workpiece support. Unstable workpieces can cause vibration and movement, leading to increased noise levels. To prevent this, it is essential to secure the workpiece properly and ensure that it is firmly supported during the grinding process. By maintaining stable workpiece support, you can minimize vibration and reduce the noise generated by the bench grinder.

Employee Awareness and Training

Educating Workers about Noise Hazards

Ensuring employee awareness of noise hazards and their potential impact is crucial for creating a safe working environment. Employers should educate their workers about the dangers of excessive noise exposure and the importance of bench grinder noise reduction. This can be achieved through training sessions, informational materials, and regular reminders about safe practices. By increasing employee awareness, workers can better understand the risks involved and take appropriate measures to protect themselves from noise-related health issues.

Promoting Safe Practices and Reporting

In addition to education, it is important to promote safe practices and encourage reporting of any noise-related concerns. Employers should establish clear guidelines and protocols for safe bench grinder operation and noise reduction. This includes providing employees with the necessary tools and resources to implement noise reduction measures and encouraging them to report any issues or abnormalities. By creating an open and supportive environment, employers can foster a culture of safety and ensure that noise-related problems are addressed promptly and effectively.

Providing Hearing Conservation Programs

To further support employee well-being and hearing protection, employers can implement hearing conservation programs. These programs typically include regular hearing tests, audiometric evaluations, and monitoring of noise exposure levels. They also provide ongoing education and training on hearing protection, as well as access to appropriate hearing protection devices. By offering comprehensive hearing conservation programs, employers demonstrate their commitment to safeguarding their workers’ hearing health and overall well-being.

Advances in Bench Grinder Technology

Innovations in Motor and Gearbox Design

Advancements in motor and gearbox design have played a significant role in reducing bench grinder noise. Manufacturers are continuously developing quieter and more efficient models by incorporating innovative technologies. These advancements include improved motor insulation, precision-engineered gear systems, and enhanced vibration control mechanisms. By investing in modern bench grinders with these innovations, users can benefit from reduced noise levels and improved overall performance.

Silent Grinding Wheel Technologies

In addition to motor and gearbox advancements, silent grinding wheel technologies have also emerged to address noise reduction in bench grinders. These wheels are specially designed to minimize noise by incorporating sound-dampening materials and unique tread patterns. Silent grinding wheels not only provide a quieter grinding experience but also offer enhanced performance and longevity. By using these advanced grinding wheels, users can achieve high-quality results while minimizing noise levels.

Integrated Noise Reduction Features

Some bench grinders are now equipped with integrated noise reduction features, further enhancing their noise reduction capabilities. These features may include built-in vibration-dampening mechanisms, soundproof enclosures, and noise-reducing components. By opting for bench grinders with integrated noise reduction features, users can enjoy a quieter and more comfortable working environment without the need for additional modifications or measures.

Case Studies: Successful Bench Grinder Noise Reduction

Company X Implements Soundproof Enclosures and Reduces Noise Exposure by 50%

Company X, a manufacturing firm, recognized the importance of bench grinder noise reduction and made significant efforts to address the issue. They installed soundproof enclosures around their bench grinders to contain and minimize noise transmission. The result was a remarkable reduction in noise exposure, with noise levels decreasing by 50%. Employees reported improved focus and productivity, along with reduced stress levels. Company X’s success serves as a testament to the effectiveness of soundproof enclosures in bench grinder noise reduction.

Worker Y Uses Custom-fit Earplugs and Avoids Noise-induced Hearing Loss

Worker Y, an employee at a metal fabrication workshop, took proactive measures to protect their hearing from bench grinder noise. They were provided with custom-fit earplugs, which offered a secure fit and effective noise reduction. Worker Y diligently wore the earplugs during their shifts, ensuring that their ears were well-protected from excessive noise exposure. As a result, they successfully avoided noise-induced hearing loss and maintained their hearing health. Worker Y’s experience highlights the importance of appropriate hearing protection and individual responsibility in bench grinder noise reduction.

Conclusion

In conclusion, bench grinder noise reduction is essential for protecting both your health and work efficiency. Excessive noise exposure can lead to various health problems and hinder your ability to perform tasks effectively. By understanding the causes of bench grinder noise, implementing effective noise reduction measures, and using appropriate hearing protection, you can create a quieter and safer work environment. Additionally, adhering to legal regulations and standards, promoting employee awareness and training, and embracing advancements in bench grinder technology can further enhance noise reduction efforts. Remember, protecting your hearing starts with addressing bench grinder noise – a small investment with significant long-term benefits.