Imagine if you could have a versatile tool that could sharpen blades, remove rust, and polish metals, all in one compact machine. The economics of bench grinder ownership uncovers the benefits and cost-effectiveness of owning this essential workshop equipment. Discover why investing in a bench grinder can not only save you time and money but also elevate your DIY projects to a whole new level. Whether you’re a professional tradesperson or a passionate hobbyist, find out how adding a bench grinder to your arsenal can enhance your productivity and elevate your craftsmanship.

1. Factors to Consider Before Purchasing a Bench Grinder

1.1 Power and Speed

When purchasing a bench grinder, one of the first factors to consider is the power and speed of the machine. Bench grinders are typically available in a range of horsepower options, and the power of the motor determines how effectively the grinder can perform specific tasks. Higher horsepower allows for more efficient and faster grinding.

In addition to power, the speed at which the grinder operates is also important. Bench grinders generally come with two speed options – a lower speed for grinding and a higher speed for polishing. The speed at which the grinder operates will depend on the type of materials you work with and the specific applications you need the grinder for.

1.2 Wheel Size and Material

Another crucial factor to consider before purchasing a bench grinder is the wheel size and material. The size of the grinding wheels will determine the type of tasks the grinder can handle. Larger wheels are better suited for heavy-duty grinding, while smaller wheels are more appropriate for precision work.

The material of the grinding wheels also plays a significant role in determining the overall performance of the bench grinder. Common wheel materials include aluminum oxide, silicon carbide, and diamond. Each material has its own advantages and is ideal for specific applications. It’s important to choose a wheel material that matches your intended use case.

1.3 Motor and Drive System

The motor and drive system of a bench grinder are essential for its overall performance and longevity. Look for a bench grinder with a high-quality motor capable of handling the workload you expect to put it through. A durable motor will not only provide more reliable performance but will also require fewer repairs and replacements over time.

Additionally, the drive system of the grinder is worth considering. Belt-driven systems are generally more durable and efficient than direct-drive systems. They also offer smoother operation and reduce the chances of the motor overheating. When selecting a bench grinder, look for one with a reliable and efficient drive system to ensure optimal performance.

1.4 Safety Features

Safety should always be a top priority when working with any power tool, including a bench grinder. Before purchasing a bench grinder, make sure it incorporates various safety features to protect you and your colleagues. These safety features may include spark guards, eye shields, and adjustable tool rests for added stability.

It’s also crucial to consider if the bench grinder has an emergency stop feature that allows you to quickly shut off the machine in case of an accident. This feature can prevent potential injuries and damages. Prioritize bench grinders that have a comprehensive set of safety features to ensure a secure working environment.

1.5 Cost and Budget

Last but not least, you must consider the cost and budget before purchasing a bench grinder. Bench grinders come in a wide range of prices, depending on their features, brand, and quality. It’s important to set a budget and determine how much you are willing to invest in a high-quality bench grinder that fits your needs.

While it may be tempting to opt for a cheaper model to save money, it’s essential to consider the long-term costs as well. Cheaper bench grinders may require frequent repairs and replacements, which can add up over time. It’s advisable to strike a balance between your budget and the quality of the bench grinder to ensure optimal performance and durability in the long run.

2. Understanding the Costs Involved

2.1 Initial Purchase Cost

The initial purchase cost of a bench grinder is the most apparent cost involved in owning one. As mentioned earlier, bench grinders come in a wide price range. Depending on your specific requirements and budget, you can find bench grinders ranging from affordable options to high-end, professional-grade machines.

When considering the initial purchase cost, it’s essential to assess what features and capabilities you need from a bench grinder. While investing in a higher-priced model may provide you with advanced features and durability, it may not always be necessary for your particular needs. Carefully consider your requirements and budget to make an informed decision on the initial purchase cost.

2.2 Maintenance and Repairs

Apart from the initial purchase cost, maintenance and repair expenses are another aspect to consider when evaluating the economics of bench grinder ownership. Like any other machine, bench grinders require regular maintenance to ensure optimal performance and longevity.

The frequency and complexity of maintenance tasks will depend on the specific model you choose and the workload it undergoes. Simple maintenance tasks typically include regular cleaning, lubrication of moving parts, and occasional wheel replacement. However, more complex repairs may be required if the grinder experiences mechanical failures or damage.

Proper maintenance and timely repairs can significantly extend the lifespan of your bench grinder, ultimately reducing the long-term costs. Consider the estimated maintenance and repair expenses associated with the bench grinder you intend to purchase and ensure you have the resources and access to necessary repairs.

2.3 Power Consumption

While the power consumption of a bench grinder may not be a significant concern for individuals, it becomes more critical for businesses or workshops that rely on multiple bench grinders operating simultaneously. Bench grinders tend to consume a considerable amount of electricity due to the motors’ power requirements.

Before purchasing a bench grinder, assess the power consumption of the model you are interested in. Higher horsepower motors typically consume more power. It’s important to factor in the additional electricity costs when budgeting and determining the overall economical impact of owning a bench grinder.

2.4 Replacement Parts and Accessories

Over time, parts of your bench grinder may wear out or suffer damage. Having access to replacement parts and accessories is vital to keep your bench grinder operational and maintain its efficiency. Before making a purchase, consider the availability and cost of replacement parts specific to the model you are interested in.

Additionally, some bench grinders may require specific accessories or attachments to perform certain tasks. These accessories, such as wire brushes or buffing wheels, may need occasional replacement. It’s advisable to research the availability and cost of such accessories to factor them into the overall ownership costs.

3. Benefits of Bench Grinder Ownership

3.1 Versatility and Convenience

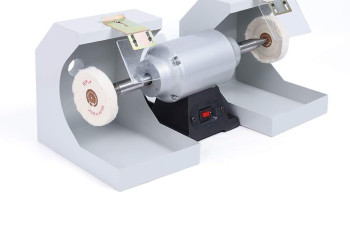

One of the primary benefits of owning a bench grinder is its versatility and convenience. A bench grinder can perform various tasks, including sharpening tools, smoothing rough edges, removing rust, and shaping metal or wood. Having a bench grinder in your workshop provides you with a single tool that can handle multiple grinding and shaping functions, saving you time and effort.

Furthermore, a bench grinder is a stationary tool that remains securely in place on your workbench. This stability allows for precise control and consistent results while grinding or polishing. With a bench grinder readily available, you can quickly and efficiently complete grinding tasks without the hassle of setting up temporary or portable equipment.

3.2 Increased Productivity

Owning a bench grinder can significantly increase your productivity, whether you’re an individual hobbyist or a small business owner. With a bench grinder, you can accomplish grinding tasks in a fraction of the time it would take using hand tools or alternative methods.

The high-speed rotation of the grinding wheels helps remove material quickly and efficiently. This translates to faster completion of tasks and more time for other activities. Additionally, bench grinders allow for precise shaping and sharpening, ensuring consistent and accurate results every time.

3.3 Long-term Cost Savings

Despite the upfront investment, owning a bench grinder can lead to long-term cost savings. By having a bench grinder at your disposal, you eliminate the need to outsource grinding tasks, saving on outsourcing costs. Moreover, the increased productivity and efficiency achieved with a bench grinder can result in higher output and revenue for small businesses.

Additionally, a well-maintained bench grinder can last for many years, reducing the frequency of replacements. Regular maintenance and timely repairs can extend the lifespan of the machine, avoiding the need for purchasing a new one prematurely. Considering the potential cost savings over the long term, the initial investment in a bench grinder can be a wise economic decision.

4. ROI: Return on Investment

4.1 Determining ROI

When evaluating the economics of bench grinder ownership, calculating the return on investment (ROI) is a crucial aspect. ROI helps assess the profitability and efficiency of an investment by comparing the initial and ongoing costs to the benefits and returns gained over a specific period.

To determine the ROI of a bench grinder, you should consider the initial purchase cost, maintenance expenses, power consumption, and any other relevant costs involved. Then, quantify the benefits gained in terms of time saved, increased productivity, cost savings from outsourcing, and reduced replacement costs.

By comparing the costs and benefits over a specified timeframe, you can calculate the ROI and determine whether investing in a bench grinder is financially viable in the long run. Keep in mind that ROI calculations vary based on individual circumstances and specific industry requirements.

4.2 Assessing Value for Money

While ROI provides a macro perspective on the financial returns, it’s equally important to assess the value for money offered by a bench grinder. Value for money goes beyond the monetary aspects and takes into account the features, capabilities, durability, and overall performance of the bench grinder.

To assess the value for money, consider the long-term benefits and costs discussed earlier, along with the quality and reputation of the brand. Evaluate the specific features and functionality that align with your requirements, ensuring that the bench grinder offers a comprehensive package that justifies its price.

Do not solely focus on upfront costs but also consider factors like safety features, ease of use, customer support, and warranty provided by the manufacturer. Evaluating the overall value for money will help you make a well-informed decision and ensure that your investment in a bench grinder is economically beneficial.

5. Considerations for Small Business Owners

5.1 Bench Grinder Size and Capacity

For small business owners, choosing the right bench grinder involves additional considerations compared to individual users. The size and capacity of the bench grinder play a crucial role in determining its effectiveness for commercial use.

Assess the scale of your operations and the tasks you anticipate the bench grinder will handle. If you work with larger materials or require heavy-duty grinding, opt for a bench grinder with a larger wheel size and higher horsepower. This will ensure that the grinder can handle the workload efficiently and deliver optimal performance.

5.2 Usage Frequency

Understanding the frequency of bench grinder usage is essential for small business owners. If grinding tasks are infrequent or limited, outsourcing the grinding operations may be a more cost-effective solution. However, if your operations involve frequent or daily grinding tasks, investing in a bench grinder becomes a viable option.

Consider the time and resources required to transport materials to an external grinding service and the associated costs. Owning a bench grinder on-site allows for immediate access to grinding capabilities, saving time and ensuring smoother workflow. Evaluate the frequency of usage and the potential cost savings to make an informed decision.

5.3 Employee Training and Safety Measures

When introducing a bench grinder into a small business or workshop, it’s crucial to prioritize employee training and safety measures. Bench grinders can be hazardous if not used correctly, and improper usage can lead to accidents and injuries.

Ensure that your employees receive adequate training on the safe operation of the bench grinder. Train them on how to properly use the machine, follow necessary safety precautions, and utilize the provided safety features effectively. Regularly reinforce safety protocols and conduct periodic refresher training sessions to maintain a safe working environment.

5.4 Cost-Benefit Analysis

Small business owners need to conduct a comprehensive cost-benefit analysis to determine the viability of bench grinder ownership. Consider the initial purchase cost, maintenance expenses, power consumption, and other relevant costs discussed earlier. Balance these costs against the potential benefits, including increased productivity, time savings, and cost savings from outsourcing.

If the cost-benefit analysis demonstrates a positive outcome, owning a bench grinder can be a cost-effective solution for small businesses. However, if the costs outweigh the benefits, exploring alternatives like outsourcing or renting bench grinders may be more financially viable.

6. Extending the Lifespan of a Bench Grinder

6.1 Regular Maintenance and Cleaning

Regular maintenance and cleaning are crucial to extend the lifespan of a bench grinder. Dust, debris, and grime can accumulate on the machine, affecting its performance and causing premature wear and tear. It’s essential to create a maintenance schedule and follow it consistently.

Perform regular inspections to identify any issues or signs of damage. Clean the grinding wheels, tool rests, and other components thoroughly to remove any debris. Lubricate the moving parts to prevent friction and ensure smooth operation. Regular maintenance not only extends the lifespan of the bench grinder but also ensures optimal performance and safety.

6.2 Proper Handling and Usage

Proper handling and usage of a bench grinder are vital to prevent mechanical failures and accidents. Always read and follow the manufacturer’s instructions and safety guidelines provided in the user manual. Ensure that the bench grinder is securely mounted to the workbench and that all safety features are functioning correctly.

When using the bench grinder, avoid applying excessive pressure on the grinding wheels. Excessive pressure can cause the wheels to wear out faster and increase the risk of accidents. Use the appropriate grinding technique, maintaining a consistent and controlled movement.

Additionally, avoid grinding materials that are not suitable for the bench grinder’s capacity or material limitations. Overloading the machine can result in reduced efficiency, premature wear and tear, or potential damage. Proper handling and usage of the bench grinder will contribute to its longevity and performance.

6.3 Choosing the Right Grinding Wheels

Choosing the right grinding wheels is essential for optimal performance and durability of a bench grinder. Different materials and tasks require specific wheel materials and sizes. Ensure that you are using the appropriate wheel for the intended application to achieve the best results.

Consider the compatibility of the wheel material with the materials you’ll be grinding. For example, diamond wheels are ideal for grinding hard materials like carbide, while aluminum oxide wheels are suitable for general-purpose grinding. Check the manufacturer’s recommendations and consult experts if needed to select the right grinding wheels for your specific requirements.

7. Environmental Impact and Sustainability

7.1 Energy Efficiency

Considering the environmental impact of a bench grinder is crucial in the modern era of sustainability. While bench grinders consume electricity to operate, investing in energy-efficient models can minimize their environmental footprint.

Look for bench grinders that are energy-efficient and comply with energy-saving standards. Energy-efficient models can significantly reduce power consumption without compromising performance. By choosing an energy-efficient bench grinder, you contribute to conserving energy resources and reducing carbon emissions.

7.2 Safe Disposal of Grinding Debris

Proper disposal of grinding debris is essential to minimize the environmental impact. Grinding operations generate metal or wood particles, dust, and other debris that can pose a risk to the environment if not disposed of correctly.

Collect and contain the grinding debris in appropriate containers to prevent it from scattering and contaminating the surroundings. Dispose of the debris in accordance with local waste management regulations. Recycle or reuse the grinding debris when possible, following appropriate recycling guidelines to contribute to sustainable waste management practices.

7.3 Sustainable Manufacturing Practices

When purchasing a bench grinder, consider the manufacturer’s commitment to sustainable manufacturing practices. Choose brands that prioritize environmentally friendly manufacturing processes and materials. Manufacturers with sustainable practices often use recyclable materials, reduce energy consumption during production, and implement waste reduction measures.

By supporting manufacturers that prioritize sustainability, you contribute to promoting environmentally conscious practices within the industry. Sustainable manufacturing not only reduces the environmental impact but also ensures higher quality and durability of the bench grinder.

8. Alternatives to Bench Grinder Ownership

8.1 Outsourcing Grinding Operations

As mentioned earlier, outsourcing grinding operations can be a viable alternative to owning a bench grinder. If your grinding requirements are sporadic or limited, it may be more cost-effective to outsource the tasks to external grinding service providers.

Outsourcing grinding operations eliminates the upfront investment in a bench grinder and reduces maintenance and repair costs. However, it’s essential to consider the additional costs, such as transportation and lead times associated with outsourcing. Evaluate the frequency and scale of grinding requirements to determine whether outsourcing is a more economically feasible solution.

8.2 Renting or Borrowing Bench Grinders

If your grinding needs are temporary or occasional, renting or borrowing bench grinders may be an alternative worth considering. Renting bench grinders allows you to access the necessary grinding capabilities when required without the long-term commitment of ownership.

Rental services or local workshops may offer bench grinder rentals at competitive rates. Alternatively, if you have a network of colleagues or friends in the same industry, borrowing a bench grinder temporarily can also be a cost-effective solution. Evaluate the frequency and duration of usage to determine whether renting or borrowing is a viable option.

9. Case Studies: Bench Grinder Ownership in Different Industries

9.1 Metalworking Industry

In the metalworking industry, bench grinder ownership is essential for efficient grinding and shaping of various metal components. Metalworkers rely on bench grinders to sharpen tools, remove burrs, polish surfaces, and achieve precise grinding results.

For metalworking businesses, owning bench grinders offers several benefits. It eliminates the need for outsourcing time-sensitive tasks, improving overall productivity. Bench grinders allow metalworkers to handle grinding operations on-site, reducing transportation costs and lead times. The long-term cost savings and increased productivity justify the investment in bench grinders for metalworking industry professionals.

9.2 Woodworking Industry

In the woodworking industry, bench grinders play a significant role in shaping and finishing wood projects. Woodworkers use bench grinders to sharpen chisels, shape wooden components, and smoothen rough edges.

Owning a bench grinder in the woodworking industry offers versatility and convenience. With a bench grinder readily available, woodworkers can quickly touch up their tools, saving time and effort. The precise control and consistent results achieved with a bench grinder ensure high-quality woodworking projects. Woodworking businesses can benefit from increased productivity and reduced outsourcing costs by investing in bench grinders.

9.3 Automotive Industry

The automotive industry also heavily relies on bench grinders for various applications. Auto mechanics use bench grinders to sharpen drill bits, remove rust, shape metal parts, and clean engine components.

For auto repair shops or mechanics, bench grinders are indispensable tools that enhance efficiency and productivity. With a bench grinder on-site, mechanics can perform grinding tasks immediately, avoiding downtime associated with outsourcing. The ability to quickly and accurately complete grinding operations contributes to smoother workflow and improved customer service. Bench grinder ownership in the automotive industry leads to substantial time savings and cost efficiencies.

10. The Future of Bench Grinder Technology

10.1 Advancements in Motor Efficiency

As technology continues to advance, bench grinder motors are becoming more efficient and environmentally friendly. Manufacturers are focusing on developing motors that deliver higher performance while consuming less energy. This shift toward energy-efficient motors contributes to reduced power consumption and lower operating costs for bench grinder owners.

Advancements in motor efficiency also translate to increased productivity and better precision. Higher-performing motors can handle heavier workloads, enabling faster grinding and improved overall performance. Investing in bench grinders with advanced motor technology ensures long-term sustainability and optimal grinding capabilities.

10.2 Enhanced Safety Features

Safety remains a paramount concern in the design and development of bench grinders. Manufacturers are continually incorporating enhanced safety features to minimize the risks associated with bench grinder operation.

Future bench grinder models may feature improved spark guards, advanced eye shields, and more precise tool rests to ensure optimal operator safety. Additionally, advancements in technology may result in the integration of smart safety features, such as automatic shut-off mechanisms and real-time monitoring systems.

Investing in bench grinders with enhanced safety features not only protects operators from potential accidents but also reduces the likelihood of damage to the equipment and workpieces.

10.3 Integration of IoT and Smart Technology

The integration of the Internet of Things (IoT) and smart technology is revolutionizing various industries, and bench grinder technology is no exception. With IoT integration, bench grinders can offer real-time monitoring and performance optimization.

Smart bench grinders may feature connectivity options that allow operators to monitor and control the machine remotely. Real-time alerts and notifications can provide updates on maintenance requirements, wheel replacements, and other crucial information.

Furthermore, incorporating IoT technology enables predictive maintenance, optimizing bench grinder performance and reducing downtime. The ability to anticipate maintenance needs based on real-time data ensures uninterrupted productivity and enhances long-term cost savings.

As bench grinder technology progresses, the integration of IoT and smart technology will continue to provide advanced functionalities and improve the overall user experience.

In conclusion, the economics of bench grinder ownership involve considering various factors, such as power and speed, wheel size and material, motor and drive system, safety features, and cost. Understanding the costs involved, including the initial purchase cost, maintenance, power consumption, and replacement parts, is also crucial. The benefits of bench grinder ownership, such as versatility, increased productivity, and long-term cost savings, make it an attractive investment. Small business owners should carefully assess bench grinder size and capacity, usage frequency, employee training, and conduct a cost-benefit analysis. Proper maintenance and handling, along with choosing the right grinding wheels, can extend the lifespan of the bench grinder. Considering the environmental impact and exploring alternatives like outsourcing or renting bench grinders are additional considerations. Case studies in different industries highlight the importance of bench grinder ownership. The future of bench grinder technology lies in advancements in motor efficiency, enhanced safety features, and integration of IoT and smart technology. As technology continues to evolve, bench grinders are poised to become more efficient, safer, and smarter tools for grinding and shaping.