If you own a bench grinder, you may have encountered some problems along the way. From dull blades to overheating motors, there are a variety of issues that can arise when using a bench grinder. But fear not! In this article, we will take a look at some common bench grinder problems and provide troubleshooting tips to help you tackle them with ease. Whether you’re a seasoned DIY enthusiast or just starting out, this article is here to help you keep your bench grinder running smoothly and efficiently. So, let’s get started!

Bench Grinder Not Turning On

Check Power Supply

If your bench grinder is not turning on, the first thing you should check is the power supply. Make sure that the grinder is properly plugged into a functioning power outlet. Sometimes, the problem could be as simple as a loose plug or a tripped circuit breaker. Try plugging the grinder into a different outlet to see if it turns on. If the power supply is not the issue, move on to the next troubleshooting step.

Inspect Power Cord

The power cord of your bench grinder could be another potential culprit for the machine not turning on. Carefully examine the entire length of the power cord for any visible signs of damage such as fraying, cuts, or exposed wires. If you notice any damage, it is crucial to replace the power cord immediately to avoid any electrical hazards. Additionally, check the connection points between the power cord and the grinder to ensure they are secure.

Replace Switch

If both the power supply and power cord are in good condition, the problem might lie with the switch. A faulty or malfunctioning switch can prevent the bench grinder from turning on. To determine if the switch is the issue, you can use a multimeter to test for continuity in the switch’s electrical circuit. If the switch fails the test, it is recommended to replace it with a new one. Make sure to disconnect the power supply before attempting to replace the switch.

Examine Motor

If none of the above troubleshooting steps have resolved the issue, it is time to inspect the motor of your bench grinder. Start by checking if the motor is receiving power by testing its electrical connections. If power is reaching the motor, but it is still not turning on, there may be internal mechanical problems within the motor. In such cases, it is advisable to seek professional assistance or consider replacing the motor altogether.

Bench Grinder Overheating

Check for Overloading

One common cause of a bench grinder overheating is overloading the machine. Grinding heavy or excessive materials for prolonged periods can put an excessive strain on the motor and cause it to overheat. To prevent this issue, be mindful of the grinding load and avoid pushing the machine beyond its capabilities. Take breaks when needed to allow the motor to cool down and prevent overheating.

Inspect the Wiring

Another potential cause of overheating in a bench grinder is faulty or damaged wiring. Inspect the wiring system of your machine, paying particular attention to any visible signs of fraying, loose connections, or exposed wires. If you identify any issues, it is crucial to address and repair them promptly. Damaged wiring can increase the risk of electrical hazards and could be a contributing factor to the overheating problem.

Verify Proper Ventilation

Proper ventilation is essential for maintaining the optimal operating temperature of a bench grinder. Ensure that there is sufficient airflow around the machine to dissipate the heat generated during grinding. Avoid placing the grinder in a tightly enclosed space or near other heat-emitting sources. Inadequate ventilation can lead to the buildup of heat, causing the grinder to overheat. Consider relocating the machine to a well-ventilated area if necessary.

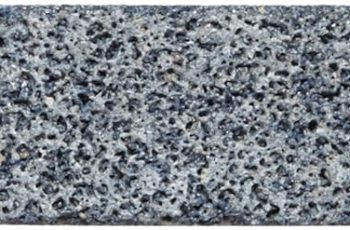

Clean or Replace the Grinding Wheels

Overheating can also occur due to the accumulation of debris, dust, or metal particles on the grinding wheels. These particles can impede the grinding process, causing the wheels to generate excessive heat. Regularly clean the grinding wheels to remove any debris buildup. If the wheels are severely worn or damaged, it may be necessary to replace them. Using worn-out wheels can lead to inefficient grinding and increased heat production.

Bench Grinder Vibrating Excessively

Check for Loose Wheel

Excessive vibration is a common problem in bench grinders and can be caused by a variety of factors. One of the first things to check is whether the grinding wheel is securely fastened to the wheel arbor. A loose or unbalanced wheel can result in excessive vibration during operation. Tighten the wheel nut or flange to ensure that the grinding wheel is firmly attached to the arbor.

Verify Proper Mounting

Improper mounting of the bench grinder can also lead to excessive vibration. Ensure that the grinder is securely fastened to a stable workbench or stand. If the mounting surface is not sturdy, vibrations from the grinder can reverberate through the surface, amplifying the problem. Consider using rubber pads or dampening materials between the grinder and the mounting surface to minimize vibrations.

Inspect Bearings

Excessive vibration can be a sign of worn or damaged bearings in the bench grinder. Inspect the bearings for any visible signs of wear, such as rust, excessive play, or noise during operation. If the bearings are compromised, they should be promptly replaced to restore the smooth and stable operation of the grinder. Consult the grinder’s manual or seek professional assistance for bearing replacement.

Balance the Grinding Wheels

If the vibration persists even after checking the wheel tightness and mounting, it may be necessary to balance the grinding wheels. Imbalanced wheels can cause significant vibration during operation. To balance the wheels, you can use a wheel balancing kit or consult a professional grinder technician. Balanced grinding wheels will not only reduce vibrations but also improve the accuracy and quality of the grinding process.

Bench Grinder Producing Unbalanced Grinding

Check Grinding Wheel Balance

Unbalanced grinding wheels can result in uneven grinding and produce an unsatisfactory finish. To address this issue, check the balance of your grinding wheels. A quick and simple method is to attach a balancing arbor and turn the grinder on. Observe if the wheels are vibrating or wobbling excessively. If imbalance is detected, proceed with balancing the wheels using a wheel balancing kit or consult a professional.

Replace Damaged or Uneven Wheels

If the grinding wheels themselves are damaged, uneven, or worn, they can contribute to unbalanced grinding. Inspect the wheels for any visible signs of damage, such as cracks, chips, or uneven surfaces. If the wheels are severely damaged, replace them with new ones to ensure a smooth and balanced grinding operation. Using damaged or uneven wheels can result in inferior grinding performance and potential safety risks.

Verify Wheel Trueness

Wheel trueness refers to the condition of the grinding wheels being perfectly round, without any irregularities or deformations. An untrued wheel can cause the grinder to produce uneven grinding results. Inspect the wheels for any signs of being out of true, such as wobbling or visible deformations. If trueness issues are identified, consult a professional grinder technician or follow the instructions in the grinder’s manual to true the wheels properly.

Adjust Wheel Dressing Tool

The wheel dressing tool is used to maintain the proper shape and sharpness of the grinding wheels. If the tool is not adjusted correctly, it can affect the balance and performance of the grinding process. Ensure that the wheel dressing tool is properly aligned and adjusted according to the manufacturer’s instructions. Regularly inspect and adjust the tool as needed to achieve consistent and balanced grinding results.

Bench Grinder Sparking

Inspect Brush Holders

If your bench grinder is sparking, it could indicate a problem with the brush holders. The brush holders hold the electrical brushes that come into contact with the commutator, transferring the electricity to the motor. Over time, the brush holders can become dirty or worn, resulting in poor contact and sparking. Inspect the brush holders for any signs of dirt, debris, or damage. Clean or replace them if necessary to ensure proper electrical contact.

Replace Worn Brushes

The brushes in a bench grinder can wear down over time due to friction and use. Worn brushes can lead to erratic electrical contact, resulting in sparking. Check the condition of the brushes and replace them if they are noticeably worn or damaged. It is advisable to use brushes recommended by the grinder manufacturer or consult with a professional technician when replacing brushes.

Clean Commutator

The commutator is the rotating part of the motor that the brushes come into contact with. Over time, the commutator can accumulate dirt, debris, or carbon buildup, hampering the flow of electricity and causing sparking. Carefully clean the commutator using a commutator cleaning stone or a fine-grit sandpaper. Be gentle and avoid damaging the surface. Regular cleaning of the commutator will help maintain an optimal electrical connection.

Check for Short Circuits

If your bench grinder is sparking excessively, it could be due to short circuits within the electrical system. Inspect the wiring and electrical connections for any signs of exposed or frayed wires that could be causing a short circuit. Additionally, check for any loose connections or damaged components that could contribute to the sparking issue. If you suspect a short circuit, it is recommended to seek professional assistance for repairs.

Bench Grinder Motor Not Rotating at Full Speed

Check for Low Voltage Supply

A low voltage supply can impact the performance of a bench grinder, causing the motor to operate at lower speeds than expected. Check the voltage supply to the grinder and ensure that it meets the manufacturer’s specifications. If the voltage is below the required level, it may be necessary to use a dedicated electrical circuit or consult an electrician to resolve the issue.

Inspect Capacitor

The capacitor in a bench grinder is responsible for providing an additional power boost during startup. A faulty or damaged capacitor can result in the motor not reaching its full speed. Inspect the capacitor for any signs of damage, such as bulging or leaking. If any issues are identified, it is advisable to replace the capacitor with a new one that matches the specifications of the original component.

Clean or Replace Armature

The armature is the rotating part of the motor that generates the grinding power. Over time, dust, debris, or worn-out brushes can accumulate on the armature, hindering its performance. Carefully clean the armature using compressed air or a soft brush to remove any buildup. If the armature is severely worn or damaged, it may need to be replaced to restore the motor’s full speed.

Test for Motor Issues

If the motor is still not rotating at full speed after checking the voltage supply, capacitor, and armature, there may be internal motor issues. Testing the motor’s components and electrical circuits requires specialized equipment and expertise. It is recommended to consult a professional technician or contact the grinder manufacturer’s customer support for further assistance.

Bench Grinder Grinding Wheels Clogging

Choose Appropriate Wheel Material

Grinding wheels can clog when they are not suitable for the material being ground. Different materials require different types of grinding wheels for optimal performance. Ensure that you are using the appropriate wheel material for the task at hand. For example, use a diamond wheel for grinding hard materials and a softer abrasive wheel for softer materials. Using the wrong wheel material can lead to excessive clogging.

Adjust Grinder Speed

The speed at which the bench grinder operates can also contribute to grinding wheel clogging. Depending on the material being ground and the wheel type, adjusting the grinder’s speed can help prevent clogging. Higher speeds tend to produce finer grinding results, while lower speeds can be more effective for heavy grinding tasks. Experiment with different speeds to find the optimal setting for your specific grinding needs.

Clean Wheels Regularly

Regular cleaning of the grinding wheels is essential to prevent clogging. Grinding generates debris, dust, and metal particles that can accumulate on the wheel surface, reducing its effectiveness. Use a wheel cleaning stick or dresser to remove the buildup from the wheel periodically. Ensure that the grinder is turned off and unplugged before cleaning the wheels. Cleaning the wheels regularly will help maintain their cutting efficiency and prevent clogging.

Use Proper Coolants

The use of proper coolants can significantly reduce grinding wheel clogging. Coolants help to dissipate heat generated during grinding and flush away debris from the wheel surface. Depending on the material being ground, different types of coolants may be suitable. For example, water-based coolants are commonly used for general-purpose grinding, while oil-based coolants are preferred for specific applications. Consult the grinder’s manual or seek professional advice to determine the appropriate coolant for your grinding tasks.

Bench Grinder Making Unusual Noise

Inspect Bearings

Unusual noises coming from a bench grinder are often a sign of worn or damaged bearings. The bearings support the rotating parts of the grinder and allow them to move smoothly. Inspect the bearings for any signs of damage, such as excessive play, noise, or rust. If the bearings are compromised, they should be promptly replaced to restore quiet operation. Consult the grinder’s manual or seek professional assistance for bearing replacement.

Replace Damaged or Worn Bearings

If the bearings in your bench grinder are damaged or worn, they can cause excessive noise during operation. Worn bearings may produce grinding, squeaking, or rattling sounds. In such cases, the bearings should be replaced with new ones of the same size and specifications. Proper installation of the new bearings is crucial to maintaining smooth and quiet grinder operation.

Lubricate Moving Parts

Insufficient lubrication can also result in abnormal noises from the bench grinder. Moving parts such as gears, shafts, and bearings require proper lubrication to operate smoothly and quietly. Check the lubrication points specified in the grinder’s manual and ensure that they are adequately lubricated. Use the recommended lubricant and follow the manufacturer’s instructions for proper application. Regular lubrication will help reduce friction and minimize noise.

Check for Loose Parts

Loose components within the bench grinder can cause excessive noise during operation. Vibrations and grinding forces can loosen screws, nuts, or other fasteners over time. Carefully inspect the grinder for any signs of loose parts, and tighten them as necessary. Pay attention to the mounting brackets, motor housing, and other structural components. Eliminating any loose parts will help reduce noise and maintain the overall stability of the machine.

Bench Grinder Abrasive Particles Shooting Out

Ensure Proper Wheel Guard Usage

One of the main safety features of a bench grinder is the wheel guard. The wheel guard prevents abrasive particles, sparks, and fragments from shooting out during grinding. Ensure that the wheel guard is properly installed and securely fastened. Never operate the grinder without the wheel guard in place. If the wheel guard is damaged or missing, replace it immediately to prevent potential injuries.

Verify Wheel Size Compatibility

Using the correct wheel size is crucial for safe grinding. If the grinding wheels are too small or too large for the grinder, it can result in abrasive particles shooting out during operation. Verify that the size of the grinding wheels matches the specifications of the grinder. Avoid attempting to use oversized or undersized wheels, as they can pose a safety risk. Consult the grinder’s manual or seek professional advice if unsure about the wheel size compatibility.

Use Safety Glasses and Face Shield

Protecting your eyes and face is essential when operating a bench grinder. Abrasive particles and sparks can fly off the grinding wheels, potentially causing eye injuries or facial lacerations. Always wear safety glasses or goggles to shield your eyes from flying debris. Additionally, consider using a face shield for maximum protection. Safety glasses and face shields should be worn by both the grinder operator and any bystanders in the vicinity.

Avoid Excessive Pressure

Applying excessive pressure during grinding can lead to the ejection of abrasive particles from the wheel. Instead, allow the grinder’s weight and the rotation of the wheels to do the work. Apply light and even pressure when guiding the material against the grinding wheels. Avoid forcing the material into the wheels, as this can cause wheel clogging, excessive heat generation, and potential particle ejection. Proper grinding techniques will help prevent abrasive particle shooting.

Bench Grinder Tripping Circuit Breaker

Check for Short Circuits

If your bench grinder repeatedly trips the circuit breaker, it is crucial to investigate for potential short circuits. Short circuits occur when there is an unintended connection within the electrical system, causing a sudden surge in current flow. Inspect the wiring and electrical connections for any signs of exposed or frayed wires that could be causing the problem. Faulty switches, damaged cords, or overloaded circuits can also contribute to short circuits.

Inspect Wiring

Faulty or damaged wiring can cause excessive electrical resistance, leading to circuit breaker tripping. Carefully examine the wiring system of your bench grinder, paying attention to any visible signs of fraying, loose connections, or exposed wires. If you notice any issues, it is vital to address and repair them promptly to prevent further electrical problems. Damaged wiring poses a hazard and should never be ignored.

Reduce Load on Circuit

If your bench grinder is connected to a circuit that is already handling a heavy electrical load, it may be overloading the circuit and causing the breaker to trip. Determine if other devices or appliances sharing the same circuit are consuming significant power. Unplug or turn off unnecessary devices to reduce the load on the circuit. If possible, consider dedicating a separate circuit solely for the grinder to avoid overloading.

Use Isolation Transformer

An isolation transformer can help mitigate circuit breaker tripping caused by electrical fluctuations or surges. An isolation transformer acts as a buffer between the power supply and the grinder, providing stable and regulated voltage to the machine. It can help prevent electrical disturbances from affecting the circuit breaker. Consult with an electrician or a qualified professional to install an appropriate isolation transformer for your bench grinder.

In conclusion, bench grinders are versatile tools that can encounter a range of problems. By following the troubleshooting steps outlined above, you can identify and resolve common issues such as the grinder not turning on, overheating, excessive vibration, unbalanced grinding, sparking, reduced motor speed, clogging grinding wheels, unusual noise, abrasive particles shooting out, and circuit breaker tripping. Remember to always prioritize safety when operating a bench grinder and seek professional assistance or guidance when needed.