Maintaining and cleaning your bench grinder is essential for its longevity and optimal performance. Regular maintenance not only keeps your grinder running smoothly but also ensures safe operation. With simple and easy-to-follow steps, you can keep your bench grinder in top condition, free from debris, and ready for any grinding task at hand.

1. Why is maintenance and cleaning important?

Taking proper care of your bench grinder is essential to ensure safe operation, extend its lifespan, and keep it performing at its best. Neglecting maintenance and cleaning can result in unwanted accidents, reduced functionality, and a shorter lifespan for your tool. By incorporating regular maintenance and cleaning into your routine, you can ensure optimal performance and longevity for your bench grinder.

1.1 Ensures safe operation

One of the primary reasons why maintenance and cleaning are important for your bench grinder is to ensure safe operation. Over time, debris, dust, and other particles can accumulate on the grinding wheels and motor, leading to decreased efficiency and potential safety hazards. By regularly inspecting and cleaning your bench grinder, you can remove any potential obstructions that could interfere with its proper functioning. This will reduce the risk of accidents and injuries while using the grinder.

1.2 Extends the lifespan of the grinder

Proper maintenance and cleaning can significantly extend the lifespan of your bench grinder. With regular inspection and cleaning, you can prevent wear and tear caused by the accumulation of debris and dust, which can lead to premature damage to the grinder’s components. By taking the time to clean and maintain your bench grinder, you can ensure that it remains in good working condition for years to come, saving you money on repairs or replacement.

1.3 Keeps performance at its best

Regular maintenance and cleaning of your bench grinder help to keep its performance at its peak. Grinding wheels that are clogged with debris or unevenly worn can result in poor grinding performance and uneven finishes. By cleaning the grinding wheels and regularly inspecting them for any signs of damage, you can ensure that your bench grinder consistently produces precise and high-quality results. Additionally, maintaining the tool rests and belts of your grinder will contribute to the overall performance and efficiency of the tool.

2. Basic maintenance tasks

To ensure the longevity and optimal performance of your bench grinder, there are several basic maintenance tasks that you should regularly perform.

2.1 Regular inspection

Regularly inspecting your bench grinder is crucial to identify any potential issues or signs of wear. Examine the grinding wheels for any cracks, chips, or uneven wear and replace them if necessary. Check for loose components, such as wheel guards or tool rests, and tighten them securely. Look for any frayed or damaged electrical connections and address them promptly.

2.2 Tightening loose components

Over time, the vibrations produced by the bench grinder may cause certain components, such as wheel guards or tool rests, to become loose. Regularly check for any loose components and tighten them securely. Loose parts can not only affect the performance of the grinder but also pose safety risks. Ensuring that all parts are properly tightened will help maintain the stability and functionality of your bench grinder.

2.3 Lubricating moving parts

Keeping the moving parts of your bench grinder adequately lubricated is essential for optimal performance and longevity. Apply lubricating oil or grease to the motor’s bearings and any other moving parts, following the manufacturer’s recommendations. Regular lubrication will reduce friction, minimize wear and tear, and enhance the overall efficiency of your grinder.

2.4 Checking electrical connections

Faulty or damaged electrical connections can hinder the performance of your bench grinder or even pose safety hazards. Regularly inspect the electrical connections, cords, and plugs for any signs of wear or damage. If you notice any issues, such as exposed wires or loose connections, disconnect the power source and consult a professional for repair or replacement.

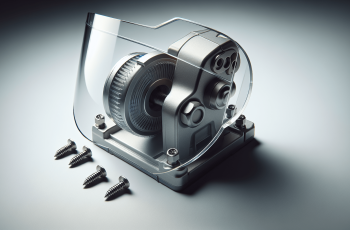

3. Cleaning the bench grinder

Properly cleaning your bench grinder is essential to maintain its performance and ensure safe operation. Regular cleaning will remove dust, debris, and other particles that can accumulate on the grinder’s surfaces and impede its functionality.

3.1 Safety precautions

Before cleaning your bench grinder, it is crucial to take necessary safety precautions. Always disconnect the power source and ensure that the grinder comes to a complete stop before beginning the cleaning process. Wear safety gloves and goggles to protect your hands and eyes from any debris or particles that may be dislodged during cleaning. Additionally, avoid wearing loose clothing or jewelry that could get caught in the grinder’s moving parts.

3.2 Removing dust and debris

Start by removing any dust and debris from the bench grinder’s surfaces. Use a small brush or compressed air to dislodge and remove loose particles from the wheel guards, tool rests, and motor housing. Be thorough in this step, ensuring that all visible dust and debris have been removed from the surfaces.

3.3 Cleaning the grinding wheels

The grinding wheels are a crucial component of your bench grinder, and keeping them clean is vital for optimal performance. Use a wire brush or abrasive cleaning stick to remove any built-up debris or metal particles from the grinding wheels. Take care to clean all sides of the wheels, ensuring that they are free from any obstructions or clogs.

3.4 Cleaning the tool rests

The tool rests provide support and stability for your workpieces during grinding. It is important to keep them clean to ensure proper positioning and accuracy. Wipe down the tool rests with a clean, dry cloth to remove any dust or residue that may have accumulated. If necessary, use a small brush to reach into any crevices or hard-to-reach areas.

3.5 Cleaning the motor and housing

The motor and housing of your bench grinder should also be regularly cleaned to remove dust and debris. Use a clean, dry cloth or compressed air to wipe down the motor and housing, ensuring that all surfaces are free from any obstructions or buildup. Check for any loose components or signs of damage while cleaning.

4. Sharpening stone maintenance

The sharpening stone on your bench grinder requires its own maintenance to ensure optimal performance and longevity. Regularly inspecting, cleaning, and dressing the stone will help maintain its effectiveness and extend its lifespan.

4.1 Inspecting the condition of the stone

Inspect the condition of the sharpening stone regularly. Look for any cracks, chips, or uneven wear on the surface of the stone. If you notice any significant damage, it may be necessary to replace the stone to maintain the quality of your sharpening results.

4.2 Cleaning and flattening the stone

Cleaning the sharpening stone involves removing any built-up metal particles or debris that may accumulate on its surface. Use a stone cleaning solution or water and a mild detergent to clean the stone. Scrub gently with a brush to remove any residue, ensuring that the stone is thoroughly cleaned. Afterward, flatten the stone using a stone flattening tool to ensure a level and even surface for sharpening.

4.3 Dressing the stone

Dressing the sharpening stone involves restoring its cutting surface by removing any glazing or unevenness. Use a dressing tool specifically designed for bench grinder stones to accomplish this. Follow the manufacturer’s instructions on how to properly dress the stone, ensuring that it is even and provides an effective cutting surface.

4.4 Replacing a worn-out stone

If you notice that your sharpening stone is significantly worn out or damaged, it may be necessary to replace it. Worn-out stones can hinder the sharpening process, resulting in less effective results. Consult the manufacturer’s recommendations or seek professional assistance to ensure you choose the appropriate replacement stone for your bench grinder.

5. Maintaining the tool rests

Proper maintenance of the tool rests on your bench grinder is essential to ensure accurate and safe grinding. To maintain the tool rests, you should regularly adjust their position, ensure proper alignment, and replace worn-out rests.

5.1 Adjusting the tool rests

The tool rests must be properly adjusted to ensure that your workpiece is adequately supported and positioned during grinding. Regularly check the alignment and height of the tool rests and make necessary adjustments. Each tool rest should be securely tightened once you have achieved the desired position.

5.2 Ensuring proper alignment

Proper alignment of the tool rests is crucial for accurate and safe grinding. Ensure that the tool rests are aligned parallel to the grinding wheels. This will provide stability and prevent the workpiece from veering off course during grinding.

5.3 Replacing worn-out tool rests

Over time, the tool rests on your bench grinder may become worn-out or damaged. Worn-out tool rests can compromise the accuracy and safety of the grinding process. If you notice extensive wear or damage on the tool rests, it is advisable to replace them with new ones. Consult the manufacturer’s recommendations or seek professional assistance to ensure you choose the proper replacement tool rests.

6. Belt maintenance

If your bench grinder is equipped with belts, proper maintenance is crucial to ensure their effectiveness and longevity. Regularly inspect and clean the belts, and replace worn-out belts when necessary.

6.1 Inspecting the condition of the belt

Inspect the condition of the belts on your bench grinder regularly. Look for any signs of wear, fraying, or damage on the belts. If you notice any significant damage, it is advisable to replace the belt to maintain the grinder’s performance.

6.2 Cleaning the belts

Belts can accumulate dust, debris, and metal particles over time, affecting their performance. Use a clean cloth or brush to gently wipe down the belts, removing any visible buildup or residue. Be careful not to apply excessive pressure or damage the belts while cleaning.

6.3 Replacing worn-out belts

If you notice that a belt is significantly worn-out, frayed, or damaged, it is important to replace it promptly. Worn-out belts can lead to reduced grinding efficiency and may even pose safety hazards. Refer to the manufacturer’s recommendations or seek professional assistance to ensure you choose the appropriate replacement belts for your bench grinder.

7. Motor maintenance

The motor of your bench grinder plays a crucial role in its performance and overall functionality. Proper maintenance of the motor will help ensure its long-term reliability and consistent power output.

7.1 Cleaning the motor

Regularly cleaning the motor of your bench grinder is essential to remove dust, debris, and other particles that may accumulate on its surface. Use a clean, dry cloth or compressed air to gently wipe down the motor, ensuring that all visible dust and debris are removed. Take care not to apply excessive pressure or damage any of the motor’s components while cleaning.

7.2 Lubricating the motor bearings

The motor bearings are critical for the smooth operation of your bench grinder. Regular lubrication will reduce friction, minimize wear and tear, and maintain the efficiency of the motor. Follow the manufacturer’s recommendations for lubricating the motor bearings, using the appropriate lubricating oil or grease.

7.3 Checking motor power and performance

Periodically checking the power and performance of the bench grinder’s motor is essential. Observe the speed and consistency of the motor while in operation, ensuring that it maintains its specified power output. If you notice any significant drop in performance or irregularities, it may indicate a problem with the motor that requires professional attention.

8. Safety precautions during maintenance

When performing maintenance tasks on your bench grinder, it is crucial to prioritize safety to prevent accidents and injuries. Follow these safety precautions to ensure a safe maintenance process:

8.1 Disconnecting power

Before beginning any maintenance tasks, always disconnect the power source and ensure that the bench grinder is completely powered off. This will prevent any accidental activation of the grinder while working on it.

8.2 Using safety gloves and goggles

Wear safety gloves and goggles to protect your hands and eyes from any debris or particles that may be dislodged during the maintenance process. This will minimize the risk of injury and ensure your safety while working on the grinder.

8.3 Avoiding loose clothing and jewelry

Avoid wearing loose clothing, such as baggy sleeves or shirts, that can get caught in the moving parts of the bench grinder. Remove any jewelry or accessories that could pose a safety hazard while working on the grinder.

8.4 Proper handling of sharp tools

During maintenance tasks that involve sharpening or dressing the grinding wheels or sharpening stone, handle the sharp tools with care. Follow proper handling techniques to avoid accidental cuts or injuries. Always use the appropriate tools for the task at hand and exercise caution.

9. Frequency of maintenance

To ensure optimal performance and longevity for your bench grinder, it is important to establish a regular maintenance schedule. By incorporating maintenance tasks into your routine, you can avoid potential issues and keep your grinder in excellent condition.

9.1 Regular maintenance schedule

Create a regular maintenance schedule for your bench grinder based on its usage and the manufacturer’s recommendations. This schedule can include tasks such as regular inspection, cleaning, lubrication, and belt or stone replacement. By following a regular maintenance schedule, you can identify and address any potential issues before they worsen and affect the grinder’s performance.

9.2 Proper storage when not in use

When your bench grinder is not in use, it is essential to store it properly to prevent dust, debris, or other elements from accumulating on its surfaces. Ensure that the grinder is stored in a clean, dry environment to minimize the risk of corrosion or damage. If possible, cover the grinder with a protective cover to further safeguard it from dust or accidental damage.

10. Troubleshooting common issues

Even with regular maintenance and cleaning, you may encounter common issues with your bench grinder. Understanding how to troubleshoot these issues can help you identify and resolve them promptly.

10.1 Grinder not turning on

If your bench grinder fails to turn on, start by checking the power source and ensuring that it is securely connected. Check the electrical connections and cords for any signs of damage or loose connections. If the power source and connections are intact, consult a professional for further troubleshooting or repairs.

10.2 Unusual vibrations or noises

Unusual vibrations or noises during grinder operation may indicate a misaligned or damaged component. Start by inspecting the grinding wheels, tool rests, and other visible components for any signs of misalignment or damage. Tighten any loose components and, if the issue persists, consult a professional for further inspection and repairs.

10.3 Poor grinding performance

If you notice a drop in grinding performance or uneven finishes, first inspect the grinding wheels for any debris, clogs, or signs of wear. Thoroughly clean the grinding wheels, ensuring that they are free from any obstructions or buildup. If the issue persists, consider dressing the stone or replacing the grinding wheels to restore optimal grinding performance.

By following these maintenance and cleaning guidelines, you can ensure the safe and efficient operation of your bench grinder for years to come. Regular inspection, cleaning, lubrication, and proper storage will help extend the grinder’s lifespan, maintain optimal performance, and safeguard against potential accidents. Remember to prioritize safety at all times and seek professional assistance when necessary. With proper maintenance, your bench grinder will continue to be a valuable tool in your workshop.